Metal 3d Printed | Questions and Answers about Aluminium

Posted By Eole Recrosio on Feb 1, 2017 | 1 comment

The last two weeks, we were talking about our new metal materials launched at CES: Titanium and Stainless Steel.

We were also announcing our new revolutionizing tool: Agile Metal Technology. This combination of tools helps you optimize and conduct a metal 3D printing project efficiently.

This week, we talk about our third metal 3D printing material: Aluminum AISi7Mg0,6.

This article explains physical and mechanical properties of Aluminum. How can you use it? Discover all you need to know before 3D printing Aluminum.

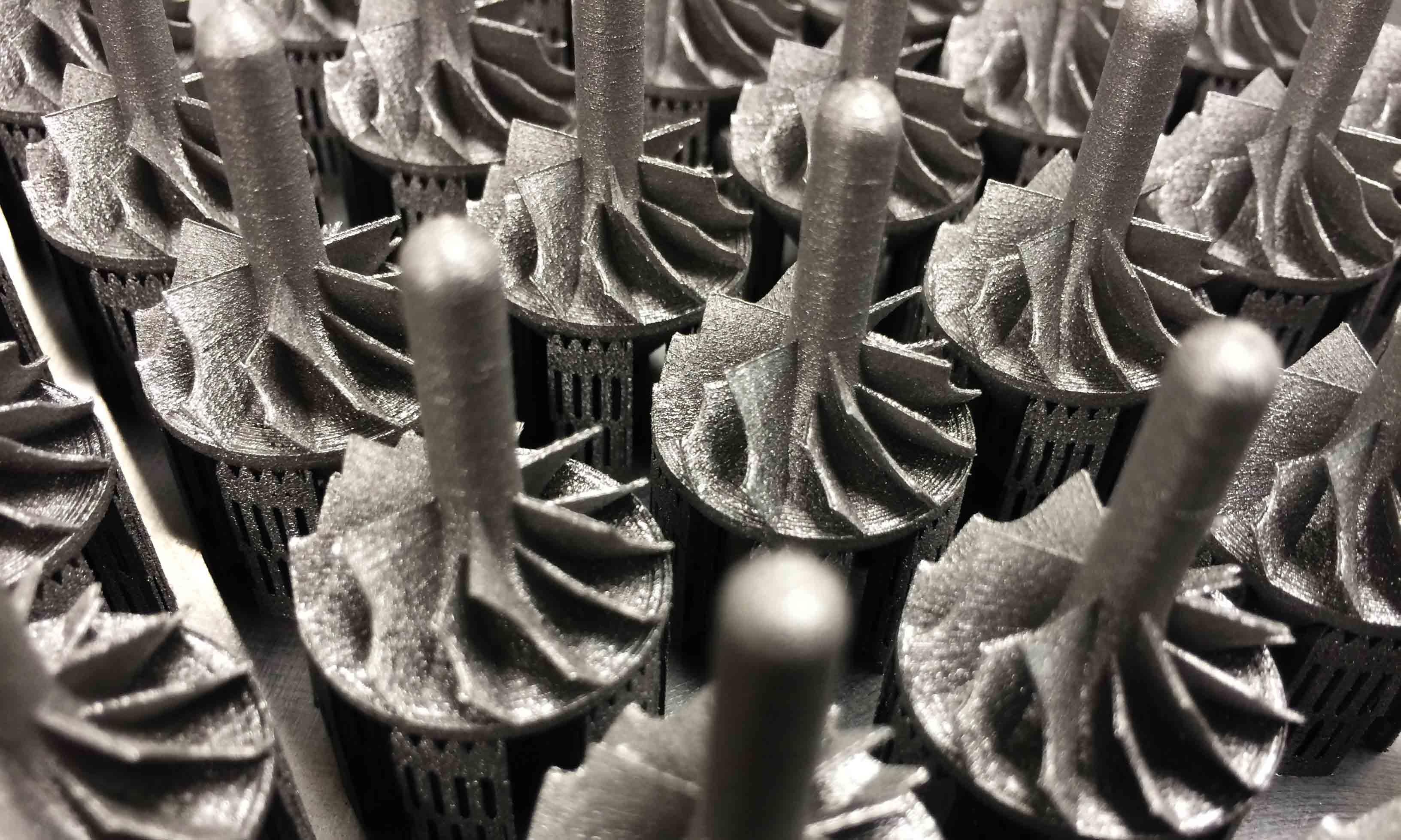

What does 3D printed aluminum look like?

3D printed aluminum has a grainy and rough surface but it is often adequate in most cases. To improve the surface, it is possible to ask for specific finishes such as polishing to obtain a smooth and shiny look.

For what parts is aluminum used for?

Metal 3D printing is not always the best solution

Our metal 3D printing materials are not beneficial for every project, that’s why we recommend you, before deciding to 3D print in aluminum or another metal to evaluate the relevance of that technology compared to other manufacturing methods like casting, machining or laser cutting.

To help you in this evaluation process, we propose our Business Case tool, the first AI for 3D printing that helps you audit your 3D printing project to get a feasibility score and precise advice and recommendations before launching your metal 3D printing project.

All the benefits of 3D printing available for metal

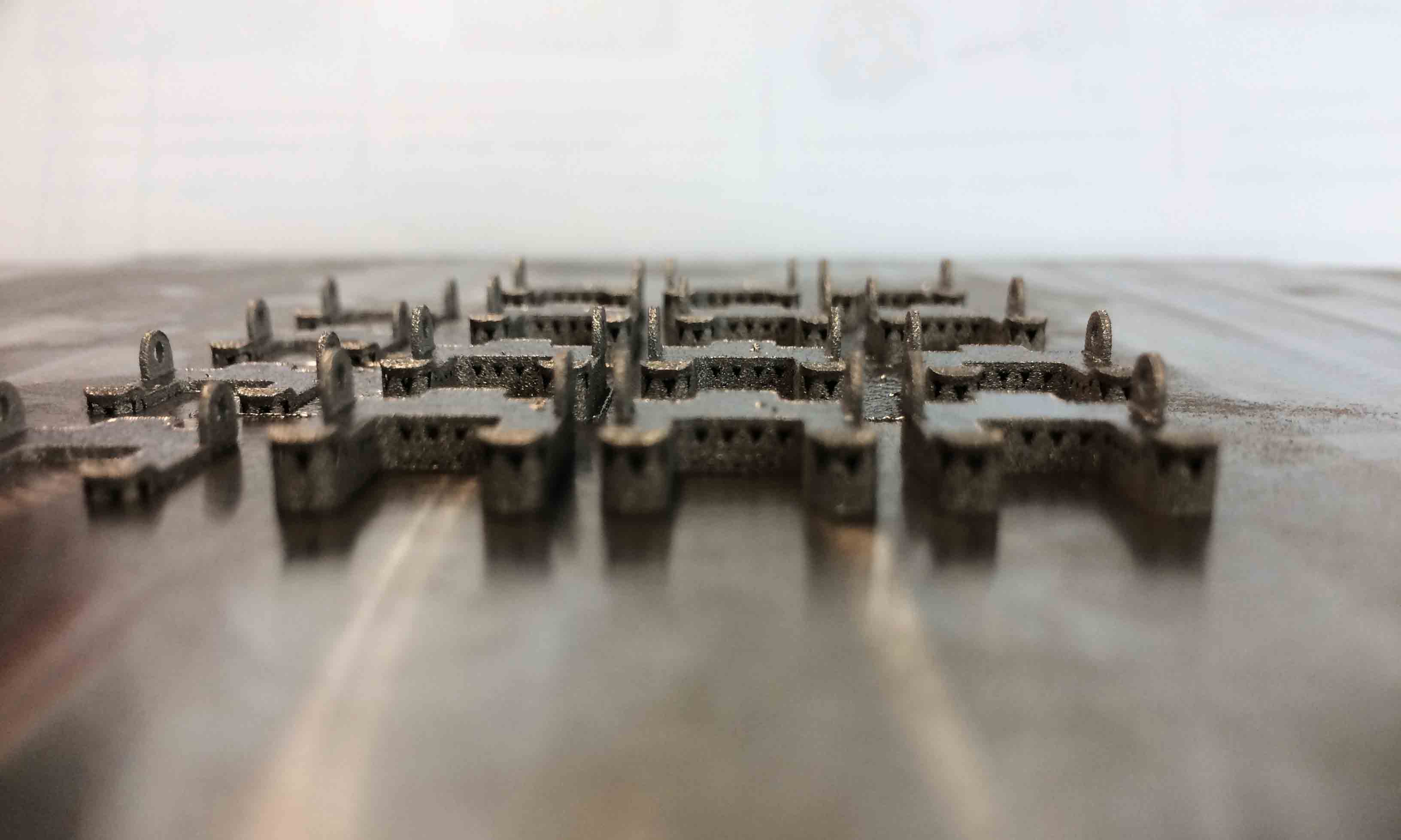

Aluminum 3D printing is especially advantageous and relevant for design with complex shapes or wireframe geometries. It is also a very good material for interlocked parts and non-demountable mechanism.

In general, metal 3D printing is very advantageous for:

- Speed

- Reduced assembly time

- Topology

- Optimization and weight reduction

- Short runs

- Mass customization

- Remote production

Aluminum 3D printed with SLM has many advantages among which building extremely complex geometries, including free form surfaces, deep groves, and cooling channels within injection molding tooling. SLM also reduces turnaround time, which is to take into account when choosing your manufacturing process.

Aluminum AISi7Mg0,6 in the Industry

Aluminum alloys allow parts to have a very good resistance combined with a very light weight. It has indeed a one of the best strength/weight ratio.

The AISi7Mg0,6 Aluminum is suitable for both prototypes and functional parts in the aerospace and automotive fields and for military applications. It is also an excellent material for the manufacture of parts with complex geometry, precision or production tooling and injection molding. Aerospace is the sector where Aluminum is often the most used thanks to its very light weight and the durability of the material.

To learn more on applications for 3D printing in general, see our application pages.

How precise is the aluminum 3D print?

Today, we 3D print a 30µm per layer for metal. For comparison, our standard resolution for 3D printed plastic is 100 – 150µm; and our high definition layer thickness is 60µm.

Can I print moving parts with Aluminum?

As SLM metal 3D printing is very complex, we cannot print moving parts with this material.

Which technology is used to 3D print aluminum parts?

Aluminum can be 3D printed with SLM and DMLS technologies.

At Sculpteo, we 3D print our aluminum with SLM technology (Selective Laser Melting) on a SLM280 HL machine.

To learn more about the metal 3D printing technologies, you can download our free guide on metal 3D printing.

How does the SLM 3D printer work?

Selective Laser Melting works additively, layer by layer to create your object according to your 3D CAD file. The feedstock powder is selectively melted by a laser to create the layers of the object. The principle is similar to SLS technology but go at higher temperatures and achieve a full melting of the powder.

How much does it cost to 3D print in aluminum with a SLM 3D printer?

Aluminum powder is an expensive material compared to polyamide powder. On our platform, once you’ve uploaded your design, the 3D printing price is calculated automatically and displayed.

Try it now by uploading a design on our platform.

If you don’t have a 3D file yet, but have a project in mind, our Business Case, the first tool of the AMT (Agile Metal Technology) suite, will ask you questions and give you an approximation of your 3D printing project cost.

You can try Business Case, the first AI for 3D printing, here.

One of the main drivers of the cost of 3D printing in metal is trial and error: because of a lack of expertise, most projects need several attempts before getting their design right for aluminum 3D printing. Our 5 upcoming Agile Metal Technology tools will reduce this back-and-forth cost by helping you evaluate the best design according to thermic constraints, in terms of supports, structure, and eventually post-process. What’s more, the tools that already exist to audit and optimize a 3D file for metal 3D printing are incredibly expensive and are not affordable for entrepreneurs or small and medium-size companies. These tools make metal additive manufacturing affordable for a larger public than it is possible today.

Are there specific 3D design constraints for Aluminum 3D printing?

Yes, like for the other metals. To help you with the design of your metal 3D printing in Aluminum, we are preparing 5 tools: the Agile Manufacturing Technology (AMT).

In many ways, metal 3D printing can be more complex than plastic 3D printing. When designing your part, you have to take into account several things:

- The thermic constraints

During the printing process, the parts endure high temperatures and cooling periods. The part can be distorted compared to your initial 3D design that’s why some modeling constraints are required to reduce these thermic constraints. Our second AMT tool after Business Case, the Smart Design Optimizer, will provide a thermal behavior simulation, for you to anticipate distortion and to avoid printing failures.

- The Mass of Your Object

The main advantage of metal 3D printing is to only use the material you need to get a physical object. The less you use matters, the less expensive it will be. We recommend reducing the amount of material used for your part by making some design optimizations. Our third AMT tool, Automatic Lattice Generator, will evaluate the forces applied to your final parts, and accordingly give advice to reinforce or lighten (and even suppress) some parts of your design with the same mechanical functions.

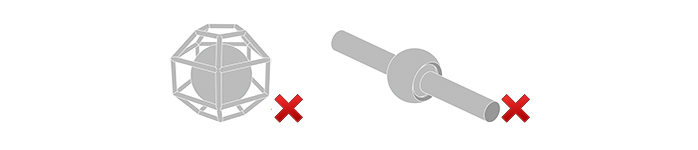

- Metal 3D printing requires supports.

Even if the powder is acting like a support, SLM and DMLS 3D printing requires specific support to attach the part and to evacuate the thermal stresses. These supports should be taken into account when designing as well, since they will influence the thermic properties of the part during the printing. Our fourth AMT tool, Interactive Support Generator, will suggest different possibilities for optimized supports.

Finishes. Post-processing is also a very important phase to consider when designing a part as it will define the final look of your object. It’s important to consider what post-process will undergo your 3D printed part. Our 5th AMT tool, Post-Processor will help you determine what finishes are needed to your part to get into the whole manufacturing process.

Discover the full AMT suite and all the tool on the Agile Metal Technology webpage.

What kind of finishes are possible with Aluminum?

Metal 3D print finishes are much more complex and technical than plastic 3D prints finishes. Our team of metal 3D printing engineers is dedicated to work with you to evaluate your project and make sure your 3D model suits your needs perfectly.

They’ll help you choose the best post-processing strategy, with finishes such as: polishing, grinding, turning, milling, drilling, threading, heat treatment.

To learn more on metal 3D printing technologies and design guidelines, you can visit our material pages or download our free guide.

If you liked this article, you can share it on Facebook, Twitter or Linkedin

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook