Maximum Size: 80x80x80mm or 115x115x40 mm (X – Y – Z)

Extensive testing and experience have shown that parts within a (X 60mm, Y 60mm, Z 60 mm) cube have the highest success rate and is suggested.

Typically, parts larger the suggested size benefit from the application of simulation and other development services. Please contact our Service Team.

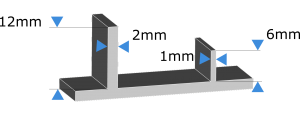

Standard Layer thickness: 150µm

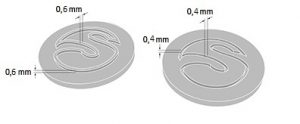

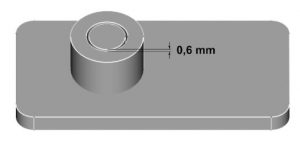

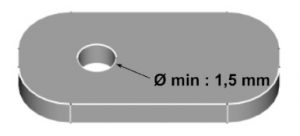

Standard nozzle size: 0,4 mm

Accuracy: +/- 1% (min 0,5mm)

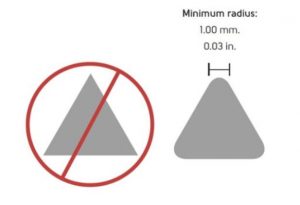

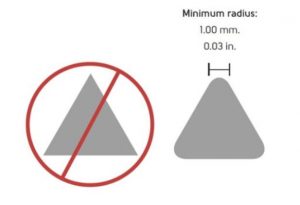

Depending on the selected nozzle diameter, sharp corners may not be printed. Please check Knife/Pointed Egdes section to overcome a potential problem.

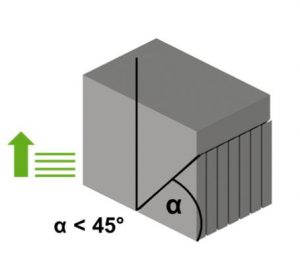

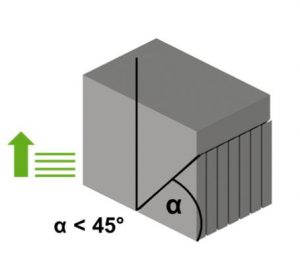

Angles under 45° require support structures.

Please keep in mind that surfaces that have connection with support won´t be as smooth as the surfaces without support.

Support structures on edges, holes and corners are difficult to remove and sometimes not possible.

Knife edges/pointed edges will likely to fail during the print process. Round all knife edges with a 1.00 mm (0.03 in.) radius to avoid failing edges.

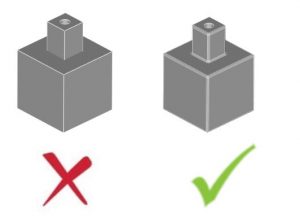

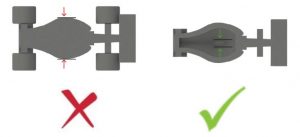

| Files with Multiple Objects ? | No |

It is not possible to 3D print a 3D file containing several objects.

It is not possible to print a 3D file containing several objects, that’s why we cannot accept files that contain clusters of multiple objects. Though, if you wish to purchase more than one identical parts, you can select the number of parts you want to order during the checkout. The more parts you order, the lower your price per part gets.

You can also use our online tools and see our tricks and tips on how to reduce your 3D printing price.

To get more information on your metal additive manufacturing service, you can contact our qualified sales team.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook