Previously, we mentioned that the printing technology you go for will define what materials you will be able to print with. No big surprise, the more advanced your 3D printer is, the more expensive the materials are going to be. As a consequence, we highly recommend you to choose your printer’s technology according to the price of the materials you can supply it with. The price discrepancies among all materials are quite high, so remember to take this into account in your 3D printing costs.

3D printing materials costs: Thermoplastics

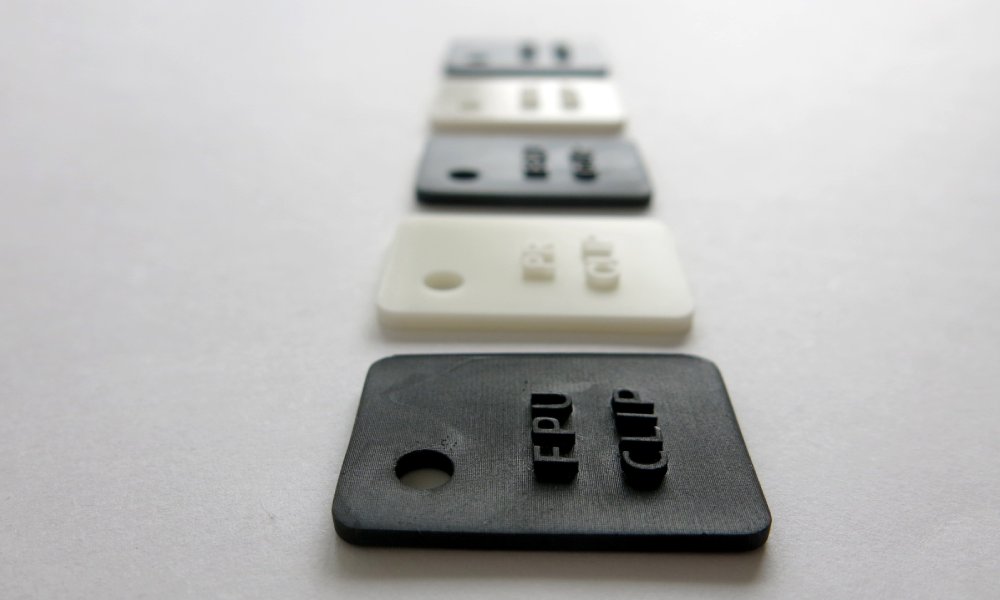

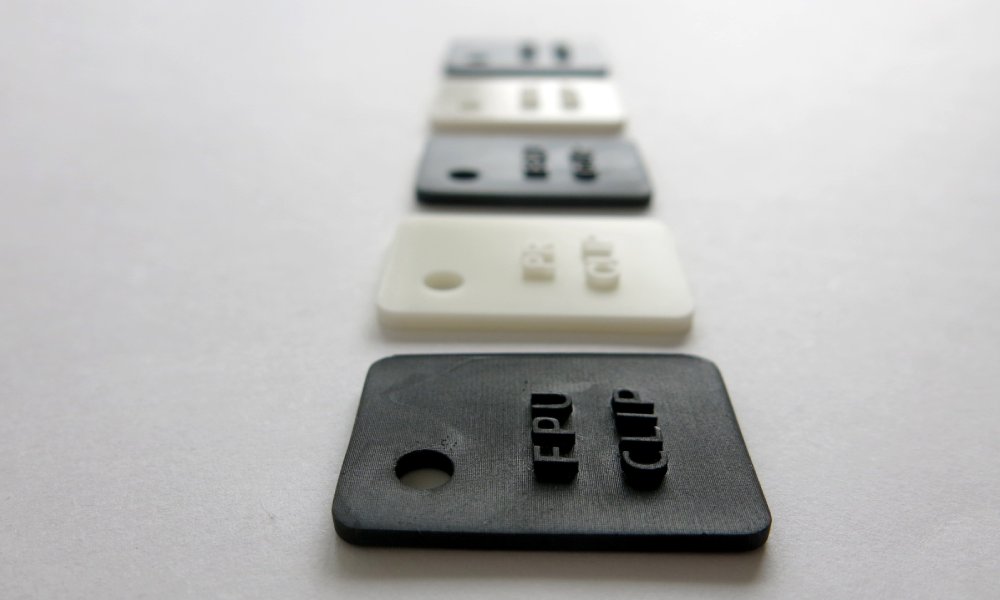

The least expensive materials you can get are those for FDM technologies. Thermoplastic filaments are the most widespread materials in 3D printing. This category encompasses different materials (PETG, PLA, ABS…) but they don’t cost more than a few tens of dollars per kilo. Then come the Nylon powders used in SLS printers. Nylon PA12, Nylon PA11/12, Nylon 3200 Glass-filled, these polymers are available in different types but their price remains overall the same. If you are considering to use our 3D printing service, these plastic materials and especially the Multi Jet Fusion PA12 are the cheapest.

Thermoplastics can be a good fit for some prototyping applications, yet the quality won’t be as good as what professional scale machines can offer. Therefore, if you want to print out a model of a final product or the product itself, the options and technologies a 3D Printing Service can offer could be a better choice than using these materials with low-detail machines.

3D printing materials costs: High-end materials

The costs of 3D printing materials naturally tend to go higher depending on how technical or precious the material. The resins you can use with Polyjet technologies (VeroWhite, VeroClear) or DLP resin 3D printers are more expensive than SLS polymers, one of the factors that justify this difference is the availability of the materials on the market.

Metals such as Aluminum AlSi7Mg0,6 and Stainless Steel 316L, used in SLM and DMLS technologies, start marking huge gaps with those previously seen, as they can cost hundreds of dollars per kilo.

Whatever the material (hence, printing technology) you are intending to use, take into account that extra finishing might be needed and have to be integrated into your total 3D printing costs.

In order for you to estimate the costs of your 3D printing project, you have to think ahead of other elements that will increase your costs. Your 3D printer and materials might represent the biggest share of your investments, but your costs don’t boil down to it. We have reviewed below other things to anticipate:

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook