Full Q&A on our new non-dyed option for our Multi Jet Fusion PA12 material

Posted By Jessica Van Zeijderveld on Apr 10, 2018 | 0 comments

With the launch of our new non-dyed option for our Multi Jet Fusion PA12 material, you might come up with some questions in your mind such as ‘’What are the characteristics of this new option and how come it is so low priced?’’ We will answer all of these questions in this Q&A. If you have a very specific question, do not hesitate to reach out to us at: [email protected]!

Q: In general, what is our Multi Jet Fusion PA12 material?

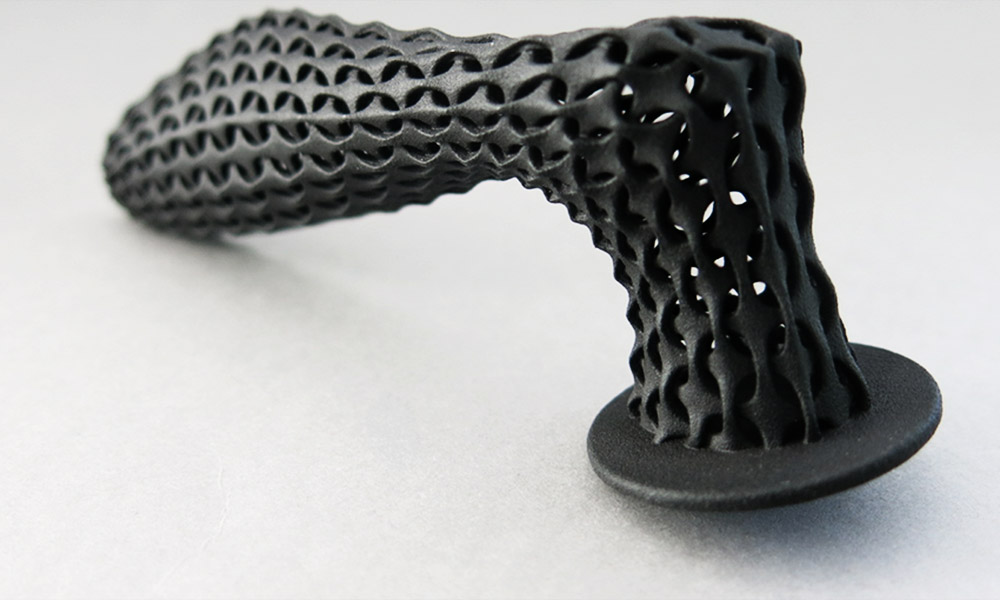

Our Multi Jet Fusion 3D printing material is a polyamide powder based material used to 3D print with our HP Multi Jet Fusion printers. The material is characterized by excellent elasticity and a high impact resistance. It is also highly resistant to external constraints. It is also able to withstand chemicals such as hydrocarbons, aldehydes, ketones, mineral bases and salts, alcohols, fuels, detergents, oils and fats.

Q: What are the characteristics of this new non-dyed option?

Our new non-dyed option for the Multi Jet Fusion PA12, is the cheapest option we offer out of all our 3D printing material options. Just like our other PA12 options, the non-dyed option consists of a polyamide based powder that is biocompatible and again, it is characterized by good elasticity and high impact resistance – making it ideal for stress tests.

Q: What does the Multi Jet Fusion process look like?

The Multi Jet Fusion technology was created by HP. It is quite similar to Selective Laser Sintering (SLS): a laser heats some parts of a batch of polyamide powder to make them fuse, layer per layer, according to the shape of the object which has to be made. The main difference with the SLS 3D printing technology is the use of a binding agent, deposited on the powder according to the object’s shape, in order to accelerate the fusion of the powder. To learn more about this additive manufacturing technology, you can refer to our page dedicated to the Multi Jet Fusion 3D printing process.

Q: Why are my parts grey when I use the non-dyed option?

When an object made with the Multi Jet Fusion technology, using MJF PA12, comes out of the 3D printer, it is grey. The polyamide powder used to create the object is white, but this additive manufacturing technology uses a binding agent to help fuse the powder particles, and this agent has a black color. Thus, the parts are grey if you don’t apply any type of finish after the 3D printing process. You can obtain black parts of high-quality by choosing a special finishing option such as Color Touch or Color Resist.

Q: What does the non-dyed option look and feel like?

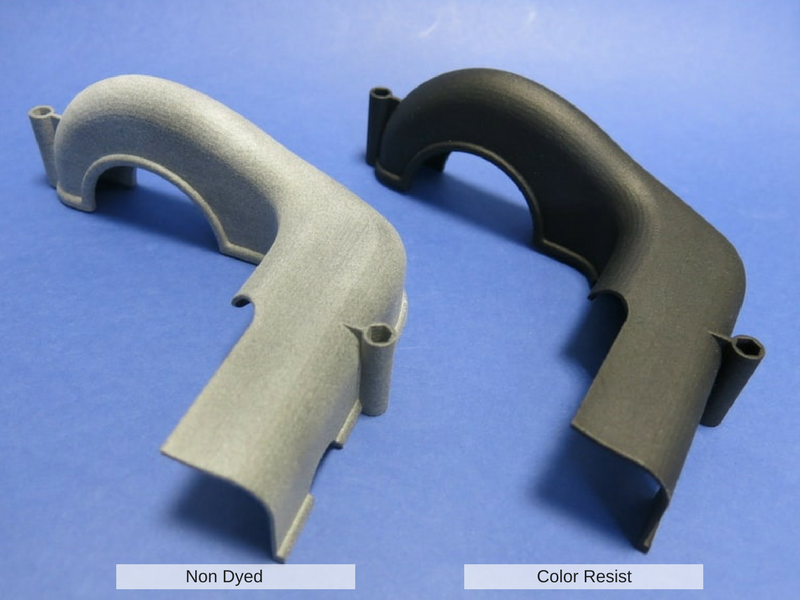

A: Non-dyed Multi Jet PA12 3D printing material has a grey color when it comes straight out of the printer. The texture of this grey color has a somewhat grainy feel which can be visible to the naked eye as well. Our dyed option of the PA12 material comes out black. You can find a side-by side comparison below.

Q: What (coloring) finishes can I apply to PA12’s non-dyed option?

As you can see in the comparison picture, we have a Color Resist finish, but we also have a Color Touch finish.

- Our Color Resist finish is a dyeing finish that gives your 3D printed parts a matte finish. This matte finish is characterized by the ability to handle friction. The process of Color Resist colors more consistently between different production batches. The available color for this finishing option is black.

- Our Color Touch finish gives your 3D printed part a satin look. This finish is able to endure daily handling and exposure to external conditions such as when scratching and rubbing occur. This dye will result in the parts being colored in black as well.

Q: What other options are there for the PA12 material?

Besides our regular non-dyed option, we also offer a polished non-dyed option. Like we said before, the non-dyed option comes with a grey finish that has a grainy feel to it. You might wish to have a non-dyed option but with a smooth surface. With our non-dyed polished option we add an additional process step that polishes your parts resulting in a smooth texture of your 3D printed parts.

Q: How come this new non-dyed option is so cheap?

Extra process steps mean more labour, time and material use. By removing an extra process step, we save time and money. We can implement these savings in our price. Due to not including a dyeing step in the printing process, we can offer our non-dyed option for a very low price. So low in fact, that it is the cheapest option we offer – not only for the Multi Jet PA12 material, but out of all of our 3D printing materials.

Q: Who should make use of this new low-priced non-dyed option?

To summarize our non-dyed option, the parts come straight out of the printer without any additional process steps resulting in a low price. The material used for our non-dyed option is a polyamide powder based material characterized by excellent elasticity and a high impact resistance to chemicals. The fact that this material has excellent elasticity, makes it an ideal option for stress tests on mechanical parts and complex models without having to break the piggy bank.

So not only is it a perfect ‘’try-out’’ material for small budgets, it is also ideal for prototyping. If you need to create multiple prototypes – but you want the costs to stay in bounds and you also wish to use a qualitative material, this non-dyed option is perfect for you. The non-dyed option is in general an excellent choice for a wide range of uses – ranging from mechanical (e.g. prototypes, articulated objects, geared systems), electrical, medical, ornamental, automotive, to even educational purposes.

Q: What are some technical aspects of the non-dyed option?

Some technical aspects of the non-dyed option are e.g. the maximum size of your object is limited to 284x350x350mm. The minimum wall thickness of your 3D model can only be 0,6mm. When you create the wall thickness of your object with a 0,6mm in mind, your object will be flexible. If you create your model with a 2mm wall thickness, your object will be rigid. For more details on technical aspects, consult here.

Ready to use this non-dyed option yourself?

Perhaps you’re part of a startup that needs to experiment with an upcoming product line? Or maybe you need to perform wear and tear tests for 3D printed mechanical parts? Whatever upcoming project you have, if a specific finish or look is not relevant for your project but quality and price is – the non dyed option for the Multi Jet Fusion PA12 is the horse you should bet on. You can upload your file today by clicking here and you will receive your 3D printed parts faster than you can say ‘’3D printing service Sculpteo“. If you have a specific question on this non-dyed option that we were unable to clarify in this Q&A, do not be afraid to contact us at: [email protected].

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook