Metalize your 3D printed designs for a luxurious quality and appeal

Posted By Stephany Vaussanvin on Nov 16, 2021 | 0 comments

Luxury is all about the feeling of exclusivity, standing out in a crowd, and creating a personalized experience. With 3D printing, luxury brands can begin to make the impossible and no longer be bound by what’s “possible.”

Industrial 3D printing has massively increased in quality in the last few years, delivering parts comparable to injection molding with smooth surfaces, no visible layers, and professional properties; as a result, additive manufacturing’s role has increased significantly in the luxury industry.

With the evolution of industrial technologies, 3D printing is now a perfectly adapted solution for series production and end-use parts. How can 3D printing help you with your luxury project? Let’s take a look at how 3D printing is paving the way for luxury products.

What is Metalization?

Metalization is the process of depositing a thin layer of metal onto the surface of an object by electroforming. Polymer parts take on the visual characteristics of a metal surface without the weight of a whole metal part. This process can add up to several millimeters to the surface. It’s important to note that the metalization process will highlight the surface quality, exposing every detail; if you want a smooth, even finish, you will need to have a smooth surface.

How does it work?

An initial tumble polishing removes rough surfaces, and a conductive layer is applied. Electrical contact is made on the part, creating an oxidation-reduction of metal ions, preparing the part to receive the metal surface. The part is immersed in a copper or nickel bath; the time spent in the bath will determine the thickness of the deposited metal (from a few microns to several millimeters).

Qualities of Metalization?

Metalization works best on all polymer and photopolymer materials like PA12 using Selective Laser Sintering technology and TPU01 using Multi Jet Fusion technology. After the metalization has been applied to these polymer materials, the results are corrosion-resistant, lightweight, air-tight, and waterproof.

Metalization is also possible on resin material, as we will see up ahead when discussing the metalization of ornate perfume bottle caps. A significant advantage of using resin for metalization is its highly smooth surface after printing, which doesn’t need polishing or a chemical smoothing process before metalization.

Metalization dramatically reduces the surface roughness of an object, making it the best surface treatment of most post-processing options. If you want to learn more about surface finishes for 3D printing and how to achieve the best quality finish for your part check out our complete guide here.

For what kinds of projects can you use 3D printing and metalization?

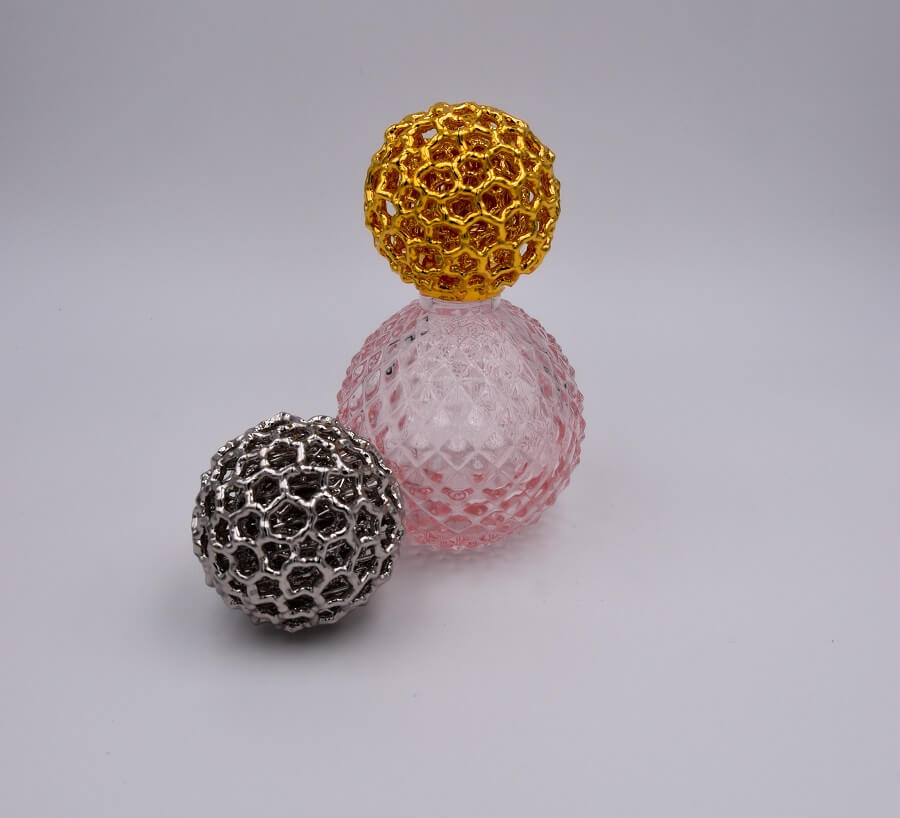

Additive manufacturing makes it possible to create complex geometries with a metalized finish that looks professional, luxurious, and highly functional. Sculpteo’s design team created perfume bottle caps to showcase the possibilities of metalization on 3D printed parts for the luxury industry. Let’s take a closer look!

Ornate Perfume Bottle Caps

The design and production process

Sculpteo Studio designed and produced ornate perfume bottle caps in just a matter of days. First, they developed several versions of bottle caps with complex geometries and styles to be printed in one batch. Then, the perfume bottle caps were printed using a resin-based 3D printing material (in this case, Ultracur®ST45) that allows for a smooth surface enhancing each design. After printing, the caps were electroplated with a thin layer of metal. Now finished, the ornate caps appear entirely made of metal and are now ready to be placed on perfume bottles. Since they are only coated with metal, the caps are lighter and do not add weight to the overall design. Resulting in a beautifully designed perfume bottle that has a look and feels of high quality and luxurious material produced in a short time and economically.

Is it possible to add metalization on flexible parts?

Sculpteo Studio also created an ornate perfume bottle cap that was flexible to the touch and had a metalized finish—giving the lid a beautiful metal look that was easy to bend without it breaking and extremely lightweight. Using TPU 3D printing material, for its robust and flexible design, a chemical smoothing process was done following printing; since the metalization process exaggerates any surface. Therefore, it is essential to have a smooth surface finish. Once the cap was chemically smoothed, a metal coating was applied using physical vapor deposition (PVD), allowing for a very thin coat of metallization and maintaining the flexibility of the TPU material. The cap doesn’t feel cold to the touch because of the very thin layer of metal coating, and the weight of the part stays lightweight.

Consult with Sculpteo Studio to see the best solutions and possibilities for your application.

Additive Manufacturing and Luxury Industry

To conclude, let’s recap all the ways AM is helping the luxury industry stay ahead of the trends to make the impossible possible.

- Customization: For any scale of production, 3D printing gives you the flexibility to print several unique parts within a single batch cost-effectively.

- Innovate and Iterate: Speed up product development time with the fastest turnaround times.

- Industrial 3D Printing Technology: Professional quality you expect from high-quality materials and finishes.

- On-Demand Production: With 3D printing, get what you need, when you need it by reducing inventory and avoiding production overruns.

For the luxury industry, 3D printing is the technology to set you apart and help you bring exclusivity and sophistication to clients. With 3D printing, shortened lead times and reactivity accelerate the design process and time to market. Produce only the quantity needed for high-end small series, with high added value and quality finishes.

Using 3D printing for complex and intricate designs for accessories or ornamentation on products is possible. What traditionally required hours of hand-crafting to create, 3D printing gives you the harness to still create original designs to produce at scale in days instead of weeks or months like traditional methods. The quality of materials and finishings, short lead times, small series, and customization make 3D printing ideal for the luxury industry.

Unleash your creativity with AM; contact the Sculpteo Studio Design team to help you get started and exploit their 10+ years of experience to your advantage for your next project! If you want to learn more about high-quality surface finishes for 3D printing, check out our complete guide here.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook