Why should you start using compliant mechanisms?

Posted By Kat Plewa on Oct 7, 2019 | 0 comments

Do you think you can design one component to control a whole device? Yes! Compliant mechanisms are truly a fascinating topic. How exactly do they work? Where can they be applied? Today we will introduce you to those mechanisms and tell you how you can improve your production thanks to them! Let’s get started.

What are compliant mechanisms?

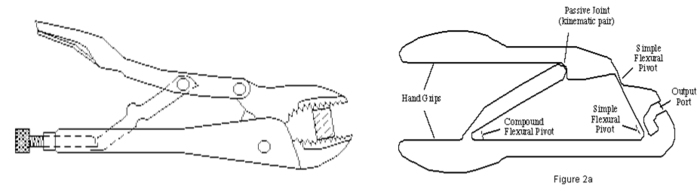

On the left-hand side, you can see a regular crimpling mechanism and on the right, an equivalent compliant mechanism.

Compliant mechanisms are used in the field of mechanical engineering. They use flexibility to transfer the force applied in one port to an output force in another. Compliant mechanisms can be made of jointless structures or single-piece (monolithic).

The main characteristic of compliant mechanisms is elasticity. They often connect two different pieces, for instance in a pump to attach an electric motor to a machine. Another application of these systems is in robotics for self-adaptive mechanisms.

Top 5 benefits of compliant mechanisms

#1 Precise motion

A very important aspect of compliant mechanisms is the assurance of precise motion. The tests have shown that those structures worked very well and the repeated motion was always accurate and precise. This is a crucial feature in industries such as automotive or aeronautics.

#2 Nanoscale applications

Compliant mechanisms can actually be used at the nanoscale and this is a very interesting application. It gives engineers a lot more freedom when it comes to designing small parts as there are fewer components needed. It also allows for more control over the whole device thanks to movable joints.

This is especially important when it comes to designing devices for space travel, where size and weight are essential. Compliant mechanisms can be made very small, but fully functional. And thanks to new technologies such as Additive Manufacturing, new materials can be used at the nanoscale. For instance, the mechanisms can be 3D printed in metal and keep their flexibility and small size.

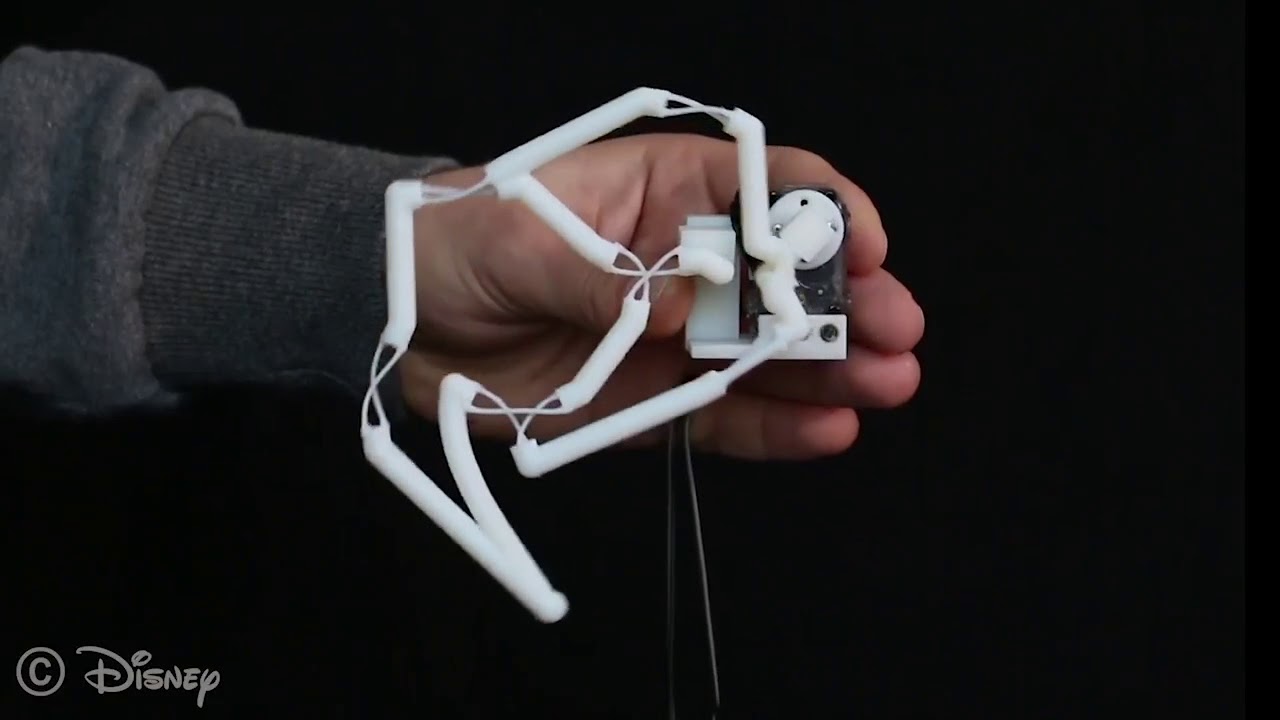

This can be applied to produce robots, for example for military surveillance or to provide rescue during disasters.

#3 More efficient production processes

As we said earlier, what is revolutionary about compliant mechanisms is their elasticity. Thanks to this they don’t require any joints or hinges to be functional, this lowers production costs. There are also fewer parts to produce, which also means faster assembly time. On top of that, they produce a lot less material waste.

Additionally, new technologies can be used with this method of designing mechanisms. Injection molding of CNC machining probably can’t produce compliant mechanisms with such good results. It can also provide you tools for topology optimization. However, this opens the door for Additive Manufacturing, which can easily handle such project.

3D printing will improve compliant mechanisms with lighter materials and new design solutions such as interlocking parts or hollowing. But most importantly, you can actually design a mechanism that can be fully 3D printed in one piece.

#4 Better performance

Compliant mechanisms mean enhanced part performance, as removing joints eliminates the risk of failure. The whole point is to produce one object which will transform force from one point to another. There are no other connectors, screws or springs, which allows the compliant mechanism to work more efficiently and perform better.

#5 Stable results

Thanks to gaining much more control over the device, reducing parts, and improved performance, you can also count on achieving stable results with compliant mechanisms. This allows you to not only save money but also trust that your device will have a lower failure risk and will be more reliable.

As you can see there are a lot of advantages of compliant mechanisms. From lower production costs, to improved performance, and absolutely new design solutions, compliant mechanisms allow you to manufacture your parts more efficiently. In addition to that, 3D printing technologies will provide you with new materials, which might be exactly what you need.

And guess what? You can start applying Additive Manufacturing to your production without even leaving your house! Compliant mechanisms or any other project, simply upload it to our online 3D printing service and change the way you produce today.

Don’t forget to sign up for our Newsletter and follow us on Facebook!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook