3D printing with plastics: what about the details?

Posted By Kat Plewa on Aug 28, 2019 | 0 comments

When you hear 3D printing, you might think about thick layers of desktop FDM printers. However, the technology has developed far beyond that. Discover 3D printing at the best quality thanks to industrial additive manufacturing! What do you need to check to achieve great detail and the high complexity of your models? Let’s talk about some tech details!

Plastic 3D printing technologies

Let’s start with how your 3D models would be printed. A technology that offers more materials and an amazing amount of details is called SLS. Selective Laser Sintering 3D printers work with plastic powder. They spread a layer of material on the 3D printer’s bed and then sinter your object with a laser beam. The laser fuses the powder locally and then the layer is cured.

Multi Jet Fusion by HP uses a multi-agent in their process. The 3D printer lays a layer of powder plastic. Then the machine applies a fusing agent and followed by a detailing agent. Lastly, the layer is cured for solidification. The process repeats until the part is built.

Details you can achieve

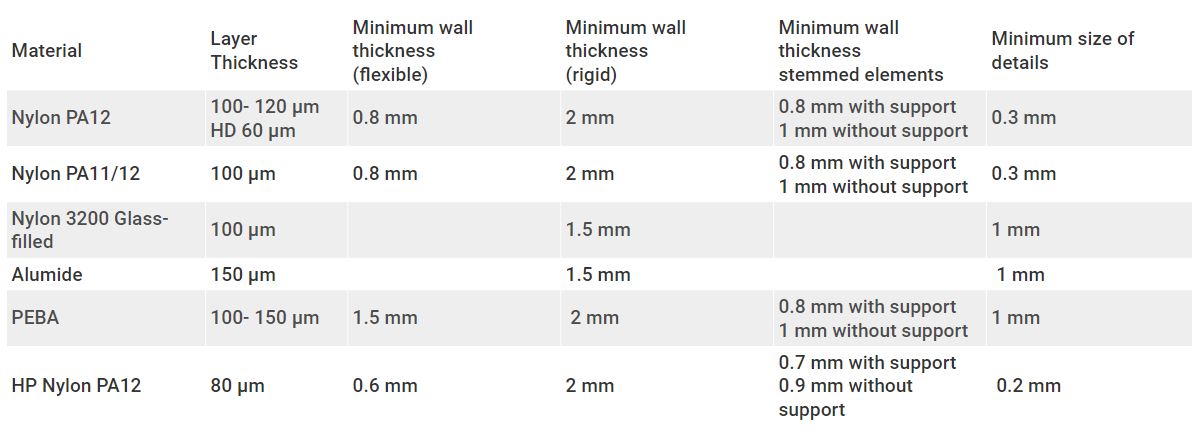

When it comes to plastic 3D printing and details, the most important thing to consider is the layer thickness, minimum detail, and minimum wall thickness. Those values differ between materials as they are used with different 3D printers. When you know those criteria, you can design the best 3D model.

Layer thickness: explained in microns (µm) where 100 µm is 0.1 mm

Minimum wall thickness (mm) the minimum thickness of your model’s walls necessary to support your model

Minimum detail (mm) the smallest amount of detail which is determined by the fusing method

Nylon PA12

This 3D printing plastic is very popular thanks to its precision and low cost. It’s solid but keeps a fair amount of flexibility. With this material, you can achieve truly stunning designs with a great amount of detail thanks to High Definition layer thickness. It is a reliable material which can give you detailed objects.

Nylon PA12 commonly used for rapid prototyping, but also end products. It also comes with various finishes giving you a lot of choices when it comes to colors and texture.

Layer thickness: 100- 120 µm

Layer thickness (HD): 60 µm

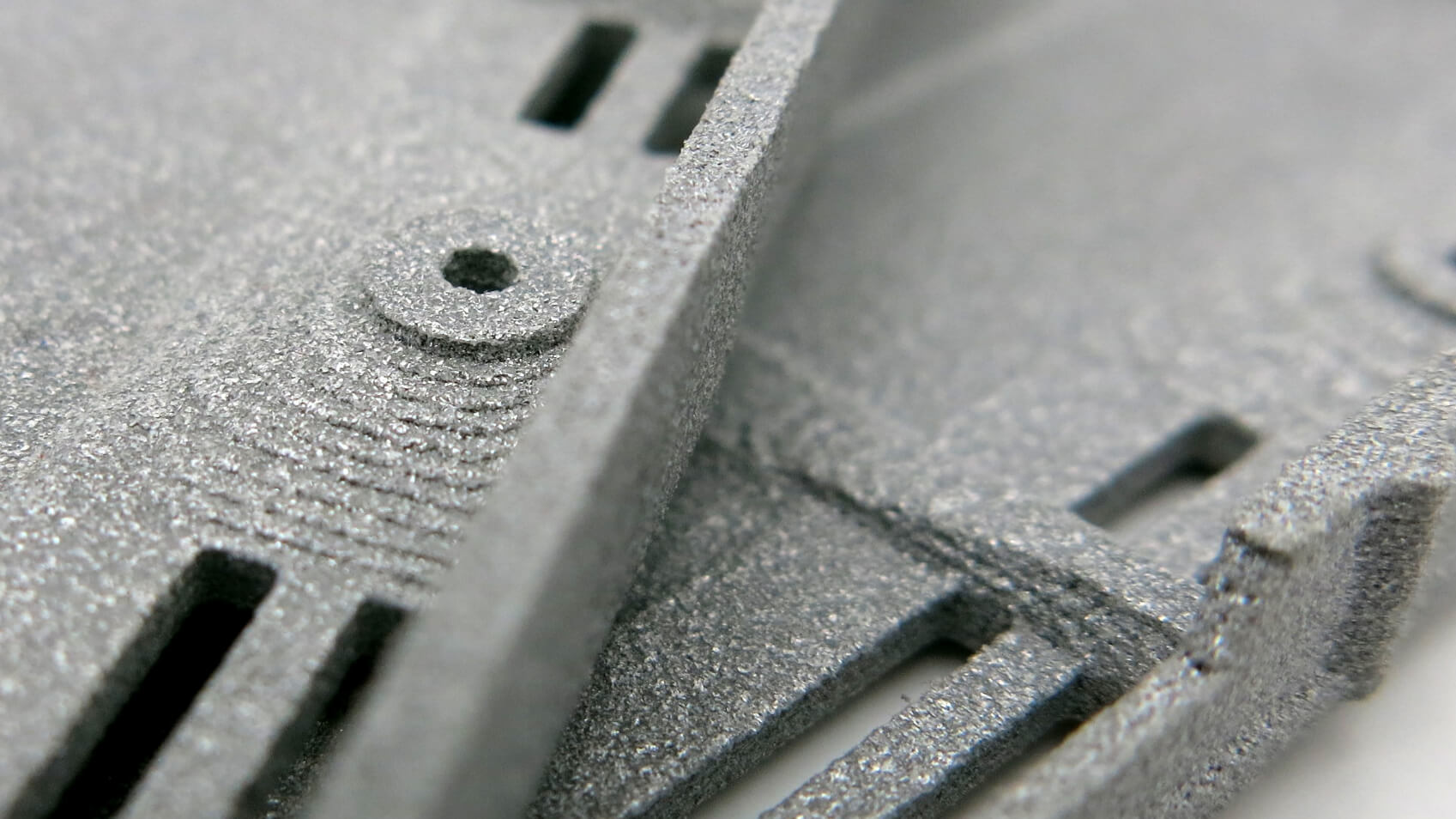

Minimum wall thickness (flexible): 0.8 mm / 1-2 mm for particular designs

Minimum wall thickness (rigid): 2 mm

Minimum wall thickness stemmed elements: 0.8 mm with support / 1 mm without support

Minimum size of details: 0.3 mm

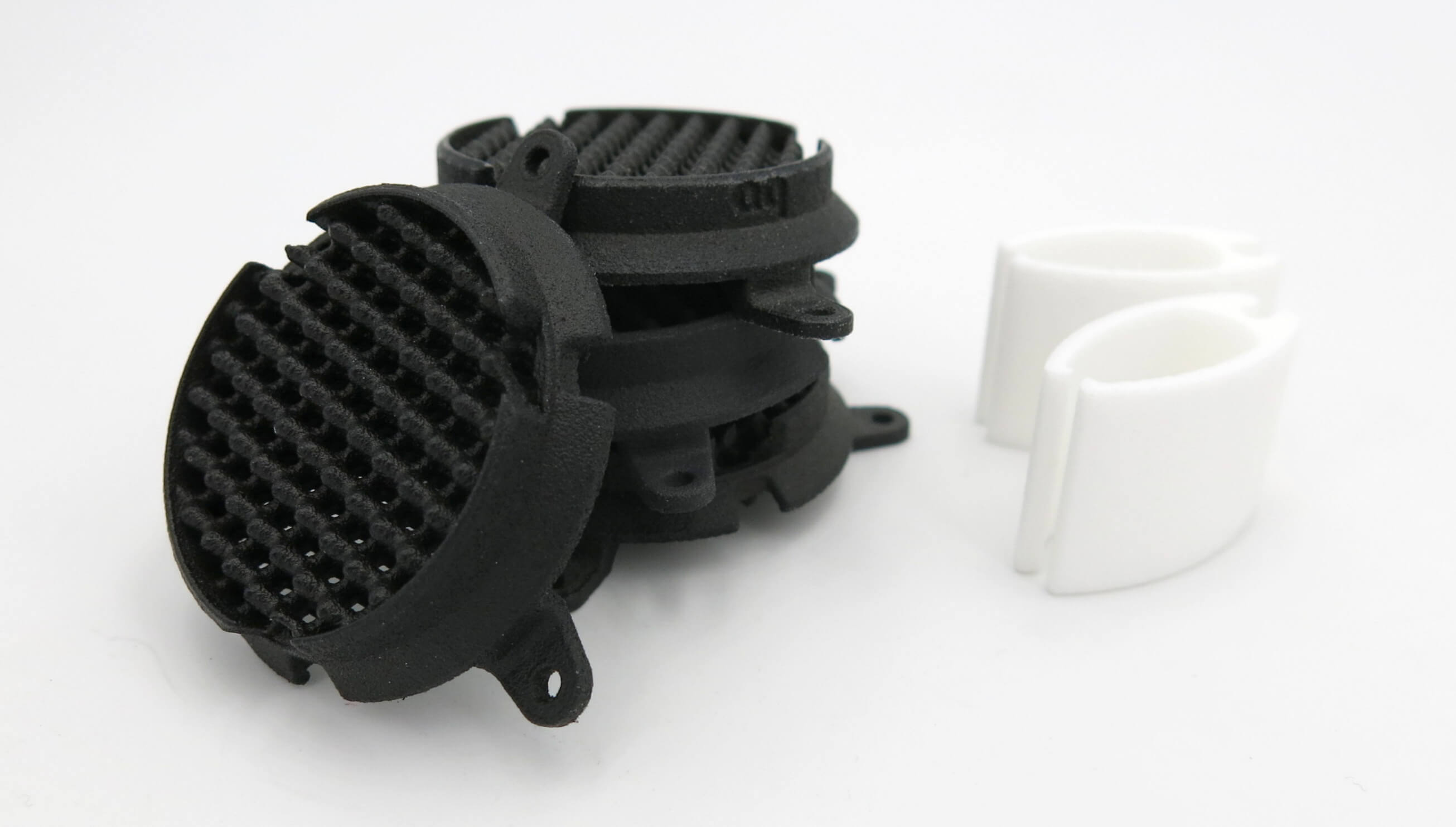

Nylon PA11/12

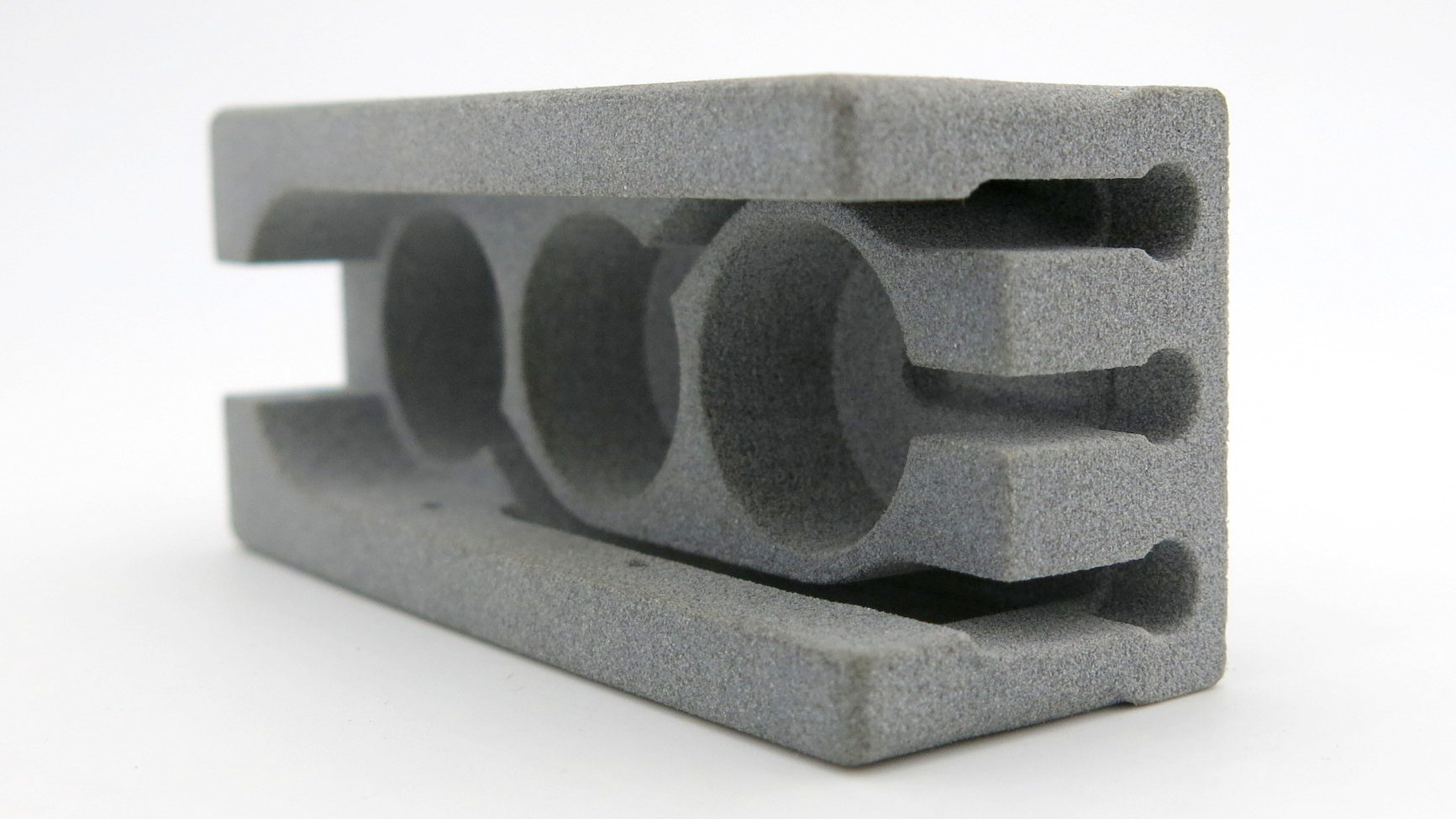

Nylon PA11/12 comes only in gray but can still achieve a high level of complexity and nice, smooth surface thanks to polishing finish. It has the properties of Nylon PA12, it’s strong and elastic at the same time. It’s resistant against abrasion and scratches. This material can give you amazing quality parts at a lower price.

Layer thickness: 100 µm

Minimum wall thickness (flexible): 0.8 mm / 1-2 mm for particular designs

Minimum wall thickness (rigid): 2 mm

Minimum wall thickness stemmed elements: 0.8 mm with support / 1 mm without support

Minimum size of details: 0.3 mm

Nylon 3200 Glass-filled

As the name suggests this material consists of polyamide powder and glass beads. The purpose of that is to achieve better durability than Nylon PA12 performs. This 3D printing powder is capable of creating complex structures and fine details.

Nylon 3200 is great for technical parts, where resistance is more important than accuracy. The material is strong and withstands lots of stress and loads. It is widely used in the automotive industry.

Layer thickness: 100 µm

Minimum wall thickness: 1.5 mm / 2 mm for particular designs

Minimum size of details: 1 mm

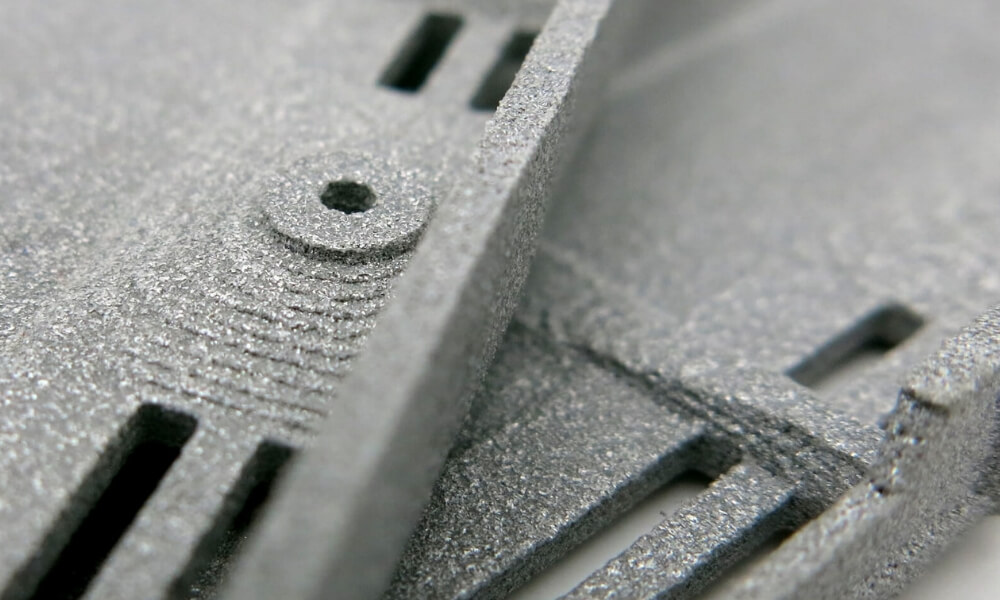

Alumide

Alumide is a very interesting material, it is a mix of fine polyamide powder and aluminum particles. It’s durable, water-resistant and economical. It can be exposed to low stress and can add the element of surprise to your model.

Layer thickness: 150 µm

Minimum wall thickness: 1.5 mm / 2 mm for particular designs

Minimum size of details: 1 mm

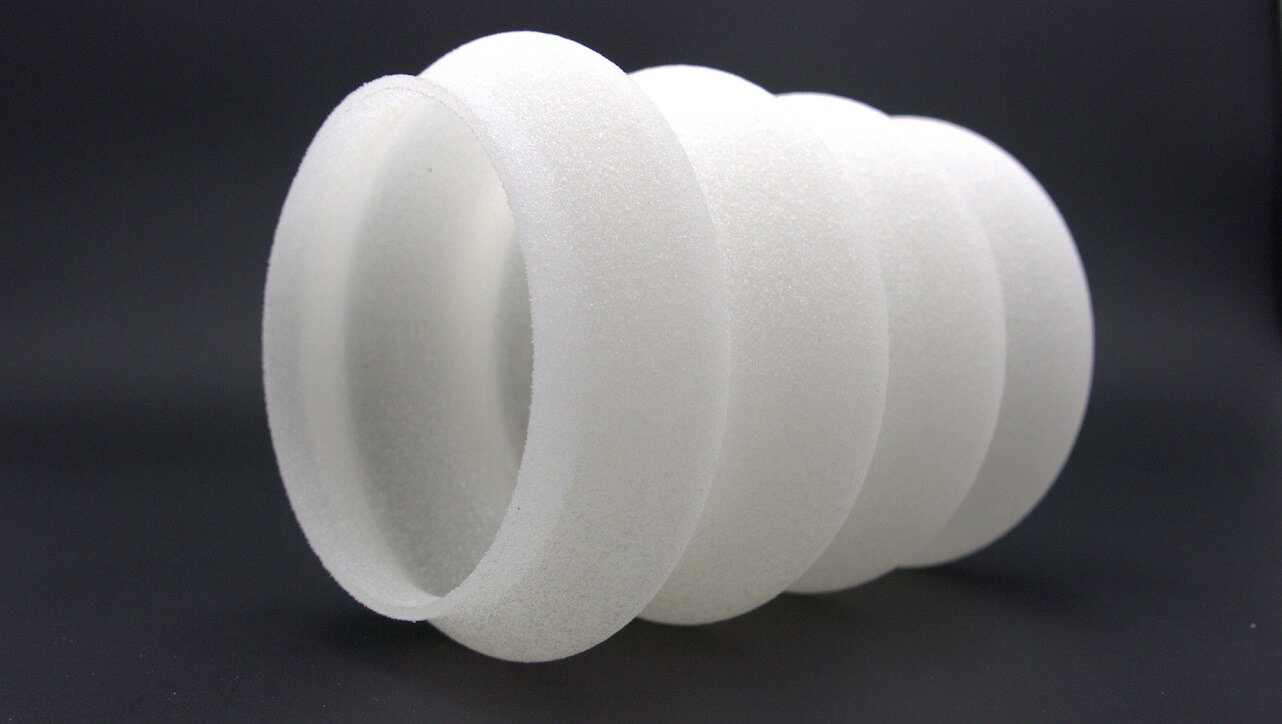

PEBA

PEBA is one of a kind plastic. What makes it special? It is flexible and rubbery, as well as resistant. It is great for functional prototypes. PEBA will provide you with accurate and precise models, so if elasticity is crucial for your project, you should take a closer look at this material.

Layer thickness: 100- 150 µm

Minimum wall thickness: 1.5 mm / 1- 2 mm for particular designs

Minimum wall thickness (rigid): 2 mm

Minimum wall thickness stemmed elements: 0.8 mm with support / 1 mm without support

Minimum size of details: 1 mm

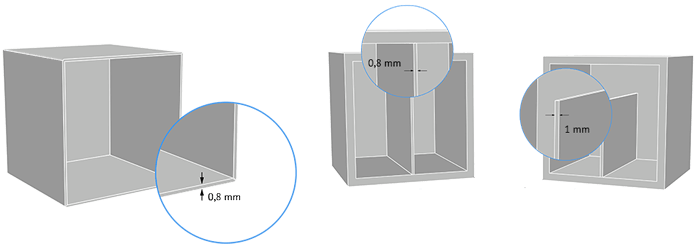

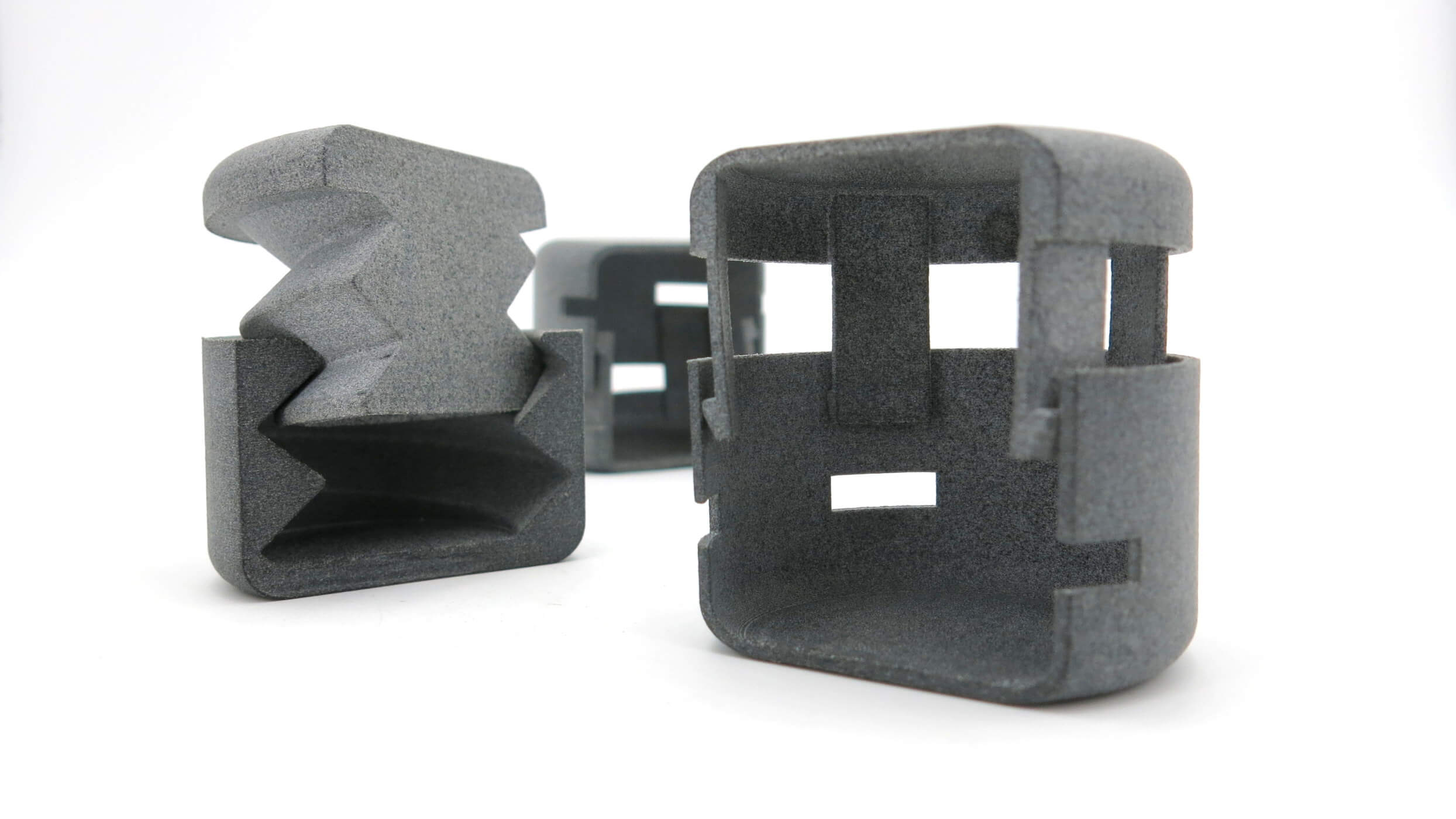

Multi Jet Fusion PA12

This fine polyamide powder is characterized by good elasticity, it’s more flexible than Nylon PA12, and high impact resistance. It is also resistant to chemicals, scratches, and abrasion. Jet Fusion PA12 is biocompatible and stable in different weather conditions. It is capable of some amazing, detailed projects thanks to the high accuracy and precision of the 3D printers.

This 3D printing plastic is suited for mechanical purposes such as gears, articulated objects, prototypes, and final products. Other industries making the most of Jet Fusion PA12 are electrical, medical, ornamental and educational.

Layer thickness: 80 µm

Minimum wall thickness (flexible): 0.6 mm / 1-2 mm for particular designs

Minimum wall thickness (rigid): 2 mm

Minimum wall thickness stemmed elements: 0.7 mm with support / 0.9 mm without support

Minimum size of details: 0.2 mm

Overview

Plastic 3D printing: what to consider?

Other than minimum wall thickness, layer and detail, there are a few more, just as important factors. We constantly work on providing you with the best tips, so your 3D printing is hassle-free! Here they come:

3D printing resolution. There are a few elements that impact 3D printing resolution and they are essential for your 3D printing to be successful. Learn more details about 3D printing resolution and how to achieve the best resolution in 3 easy steps.

Part orientation. This aspect of Additive Manufacturing directly affects your part’s stability and quality. Find more about choosing the best part orientation for your 3D printing.

3D printing tolerances. They are essential volumes, for example, maximum size, accuracy or shrinkage, that you have to take into consideration. Otherwise, you’re facing quite a few issues, the 3D printer might not be able to manufacture your object, the model will come out faulty. Read more about 3D printing tolerances.

We also have for you the ultimate guide to assure your 3D models are printable. We listed for you the top 13 ways to ensure successful 3D printing.

Start 3D printing with plastic today!

Don’t get too overwhelmed with how much there is to think about when it comes to 3D printing. The biggest thing is to have a 3D file. Once you do, all you have to do is to upload it to our online 3D printing service and we will take care of the rest! And, if you have any concerns, you can always consult with our 3D printing experts on your project.

Don’t miss the next dose of 3D printing tips! Subscribe to our Newsletter and follow us on Facebook!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook