State of 3D printing: Improving the consumer goods manufacturing process thanks to 3D printing

Posted By Lucie Gaget on Jul 17, 2018 | 0 comments

3D printing is used in a lot of different sectors. Thanks to our study, the State of 3D Printing 2018, we had the opportunity to analyze the different uses of 3D printing for different sectors. We already saw the use of 3D printing for the industrial goods sector, but in this blog post, we are going to focus on consumer goods. This study actually helps us to get a great overview of the use of additive manufacturing in this sector. 57% of our respondents saw a greater ROI on their 3D printing activity, thus we can say that the additive manufacturing technology is a real asset for this sector. The use of additive manufacturing for consumer goods seems quite promising. Let’s see more in details how this sector is making the most of this technology.

Don’t forget to download our State of 3D printing for free if you want to know everything about the 3D printing world and the use of this cutting-edge technology!

More 3D printing beginners in this sector

If we take a look at the consumer goods sector, we can see that there are more beginners (16%) and intermediate users (53%) using the 3D printing technology in this sector, compared to industrial goods and aeronautics, two other sectors we also focused on in our State of 3D printing.

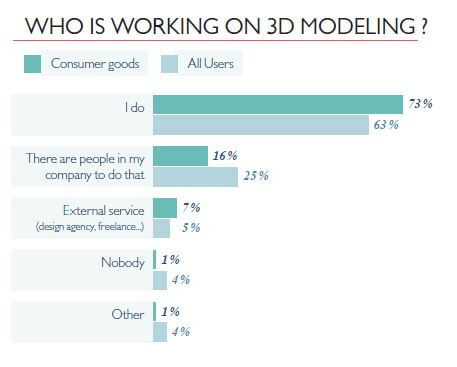

How can we explain this? This sector starts to see the advantages of this technology, and it is also starting to use 3D printing for various applications, for prototyping, but also more and more for production. Moreover, we can see that 73% of the respondents are dealing with 3D modeling by themselves. Thus, we can assume that they are learning and developing their own 3D printing skills.

Advantages of 3D printing for the consumer goods sector

Mass customization and small batches

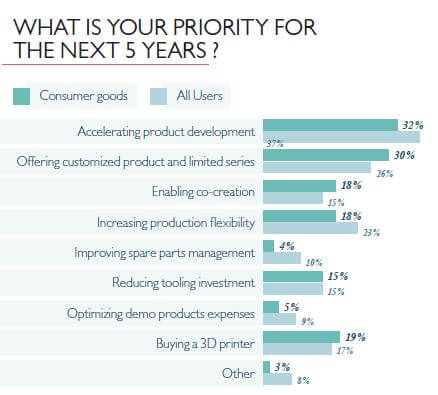

Offering customized products and small series is a big priority for 30% of our respondents in this sector.

3D printing is allowing to work on complex geometries and elaborated designs, which is a real advantage for this sector, as products sometimes have to be adapted to customers. It is making it easier and cheaper to print small batches and, for the consumer good sector, it is actually a huge benefit to get the possibility to print custom made products this easily.

Costs and lead time reduction

Acceleration of the product development process is also a priority in this sector for 32% of our respondents. By improving their prototyping and production process, they are actually saving time, developing projects faster, and saving money by using cheaper materials and an efficient manufacturing process.

Companies can develop elaborated designs faster using efficient 3D software, and make many iterations in no time. It is a real asset in this sector.

How does the consumer goods sector use additive manufacturing?

3D printing with plastic

Plastic is used by 74% of our respondents. It is clearly the most convenient material, allowing to work on complex designs, but it is also a good material to reduce costs. Indeed, plastic is one of the cheapest materials on the market. On our online 3D printing service, the cheapest option is the non-dyed Multi Jet Fusion PA12. This is the perfect solution if you want to lower the costs of your prototyping process for example. It is also possible to produce using a plastic material, it is possible to get really good results, that is why this material is so useful for the consumer goods sector Moreover, plastic materials can be used for various applications, and to develop all kind of products.

At Sculpteo, we are offering a lot of different plastic materials for your additive manufacturing projects. Check out our blog post on how to choose the best plastic material if you need a little help to get started with your 3D printing project.

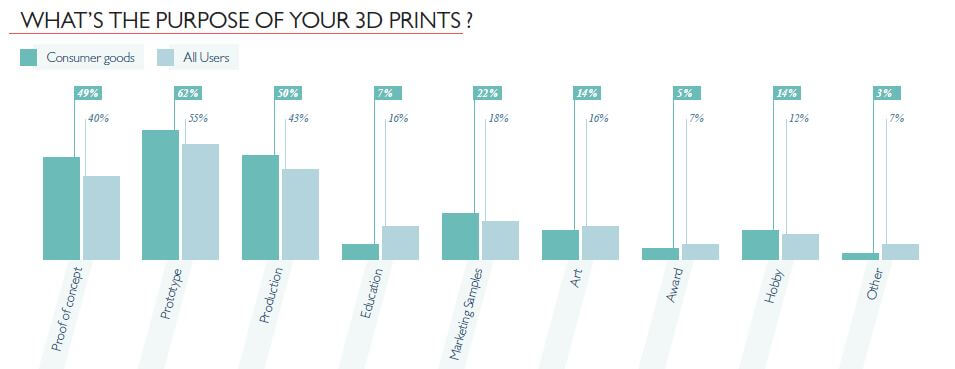

Prototypes and production using 3D printing

Additive manufacturing is a great prototyping tool, used by 62% of our respondents in this consumer goods sector. This technology is more used for prototyping than in other sectors, this is also linked to the will of companies to accelerate the whole product development process. 3D printing is allowing to iterate for lower costs. Moreover, the process is quite easy, as they just have to modify their 3D files on their 3D modeling software to get a new 3D printed version of their object. It is a real opportunity to save time.

50% of the respondents are using additive manufacturing for production. The evolution of the 3D printing technology is really fast, and this manufacturing technique is now allowing to print really good finished products. Moreover, a lot of finishes can be applied to the 3D printed parts for an even better result!

As you can see, the consumer goods sector is really starting to make the most of the additive manufacturing technology by using it on more and more levels. Companies are now able to improve their whole manufacturing process thanks to 3D printing.

Thanks to our State of 3D printing 2018, we can analyze the use of 3D printing by different sectors, like industrial goods and aeronautics. Don’t hesitate to download our full study, and to subscribe to our weekly newsletter to get all the news about additive manufacturing.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook