3D printing finishes for outdoor use: Our special tips

Posted By Marianna Papageorgiou on Jan 31, 2018 | 0 comments

The Additive Manufacturing field is progressing really fast and everyday researchers and scientist are coming up with various 3D printing innovations. There are currently so many 3D printing materials, technologies and finishes that it is impossible not to find the best one for your application. A very common requirement for our customers and many users of the 3D printing technology is to find the best 3D print finishing option for outdoor use. So, in this article we will go through some of our best finishing options you can apply to your 3D printed parts for outdoor use. Moreover, we will see some alternatives to 3D printing, such as Laser Cutting materials dedicated to outdoor activities.

DyeMansion finish: The best 3D printing finish for outdoor use

Recently we introduced you to two “DyeMansion” finishes that can be applied on your 3D printed plastic parts. Through a complete Q&A about “Color Touch” and “Color Resist” finishes, we discovered their properties and how they can meet your needs.

So what is their major benefit? “Color Touch” and “Color Resist” finishes are the perfect choices to apply to your 3D printed plastic parts to be exposed outdoors. Both of the finishes are resistant to scratching and UV resistant, as they can prevent the “yellowing” color alteration of your Nylon 3D printed parts that may occur with the exposure to sunlight. Indeed, during the sunny days, sunlight is stronger than usual, and you will need a surface that is resistant to outdoor applications and reflects sunlight. So let’s look a bit closer at these two 3D printing finishings:

- “Color Touch” finishing option is available in 14 colors (blue, black, red, green, orange, yellow, brown, pink, white, violet, navy, bordeaux, anthracite and stone gray) and gives your 3D plastics a satin look. Thus, this 3D printing finish can be applied to any plastic part that needs a smooth and elegant surface, such as glasses, fashion items, jewelry etc.. Most important of all, “Color Touch” is a UV resistant finish that withstands daily handling. You can use your 3D parts on a daily basis outdoors without color alteration, even for long periods of time. Our clients have tested this finishing option for more than 2 years and the surface of their parts are still UV-stable and brilliant!

- “Color Resist” finishing option is also available in 14 colors (blue, black, red, green, orange, yellow, brown, pink, white, violet, navy, bordeaux, anthracite and stone gray) and gives your 3D plastic parts a high-quality matte surface. Thus, it is the ideal finishing option to apply to your 3D plastics parts that need to be homogeneously colored and used outdoors. It is the perfect choice for products that will be exposed to external conditions and thus require extra resistance to scratching, friction and abrasion. Many of our clients also use it for colored 3D parts that come out of different production batches, as it allows consistent color tones.

Smoothing Beautifier: Waterproof finish for 3D printed plastics for outdoor use

At Sculpteo we have launched this patented process called “Smoothing Beautifier” that allows for a smoothed surface on 3D printed plastic parts. Its exceptionally smooth and elegant surface is not its only benefit. The most important asset of “Smoothing Beautifier” is that it’s waterproof!

At our waterproof plastic testing, we ran into the conclusion that among our raw plastic parts (Nylon PA 12 parts and Multijet Fusion PA12), “Smoothing beautifier” is the finishing option that is recommended for long-term exposure to water. That said, it can be used for outdoor use, on 3D plastics that will be exposed to rainy environments, as it does not run any risk of absorbing water. This 3D print finishing option can be applied to any 3D printed part made of plastic Nylon PA12 of maximum dimensions: 140x250x90 mm and of minimum dimensions: 15x15x0.5 mm. Currently the available colors are only black and white.

In our dedicated blog post about waterproof 3D printed plastics, you can read more about the waterproof properties of our “Smoothing Beautifier” finish and how it can fit your needs!

Plating: Anti-oxidation 3D printing finish for your 3D printed metals for outdoor use

But how do the other 3D printing materials, apart from the plastics, perform in outdoor use? Let’s take the example of our Brass 3D printing material. Brass is a metal that is oxidised in air, especially in humid conditions. The solution against oxidation is plating. Through our online 3D printing service, you can find plenty of options to apply plating your 3D printed brass parts. White Rhodium, Black Rhodium, Gold plating and Pink Gold plating are the available plating options we offer. In this article, you can find even more detailed information about each one of our plating options. Each finishing option gives a different color surface, but all of them serves as protection against oxidation, thus your 3D printed brass parts won’t run any risk of alteration.

Laser Cutting vs. 3D printing for outdoor use

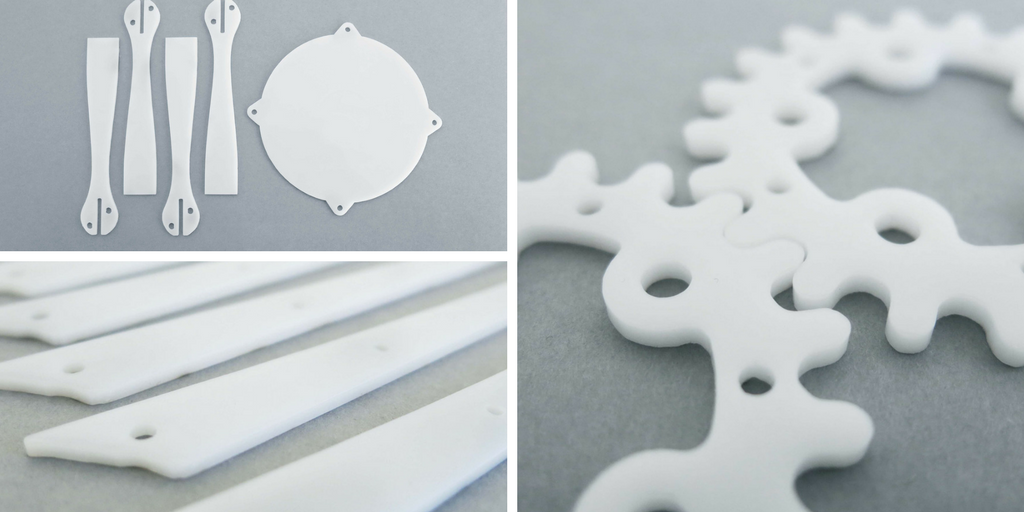

Do you want to use a material that can withstand the environmental conditions in outdoor applications, but you realise 3D printing is not the technology that fits your needs? Sometimes, the Laser Cutting technology finds better applications, like in the case of one of our customers. The iTabNav company found out that for them Laser Cutting was a better choice than 3D printing. This company produces accessories dedicated to the use of tablets on boats, including waterproof and shockproof cases, specific mounts, waterproof solar panels, or accessories dedicated to other outdoor activities. For theses applications, they used our POM Laser Cutting Material as it was the best choice. They used POM because it is a fully stable and rigid material, so it can support their projects. Also, it was cheaper than the 3D printing materials that they tried. You can read more about the benefits of Laser Cutting over 3D printing for this case, in this blog post.

POM Laser Cutting material: Weatherproof and Resistant

Our POM Laser Cutting material is particularly used for outdoor activities as it is waterproof and weatherproof. Also, it is resistant to many solvents and thus it is often used to create motor parts that need to be bathed in oil for long periods of time.

Moreover, it is suitable for technical applications, as it is resistant to cracking, and can be used in projects that need to endure large amounts of strain and friction.

Our POM material is currently available in black and white colors, and three thicknesses: 2, 3 and 5 mm. You can check it out here and see how it can be an asset for your future projects.

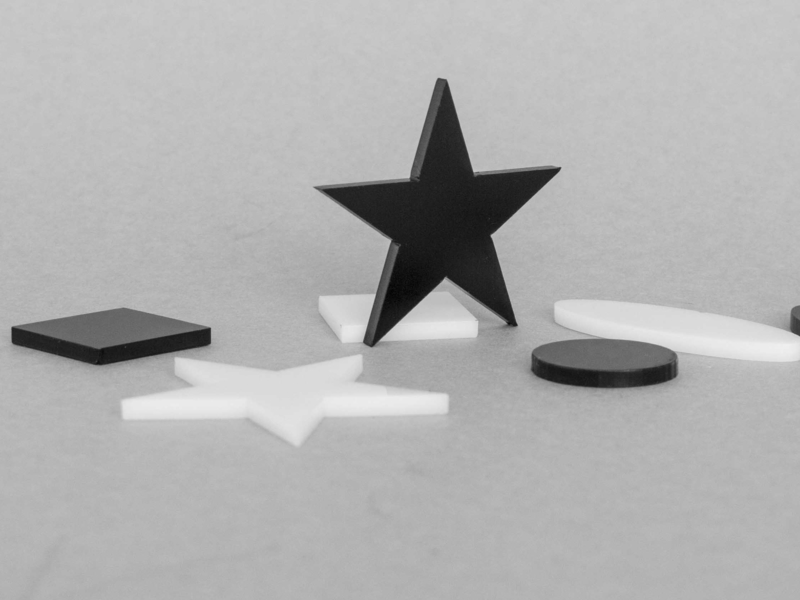

Acrylic Laser Cutting material: Waterproof and Weatherproof

Our Acrylic material is another perfect solution for manufactured parts that need to be used outdoors. It is available in 17 colors and 5 thicknesses and all of them are waterproof. That said, they are resistant to moisture and consequently they can also be used indoors, for example in kitchens and bathrooms. If you want to learn more about the properties of acrylic and its technical specifications, we invite you to visit the material page about acrylic.

To sum up, if you want some customized manufactured parts for outdoor use, you have plenty of options to choose from! Through our online 3D printing service you can find anything you need:

- waterproof, weatherproof and UV-resistant 3D printing finishes for plastics, such as “Color Touch”, “Color Resist” and “Smoothing Beautifier”

- 3D printing finishes for brass material against metal oxidation in air, such as: “White Rhodium”, “Black Rhodium”, “Gold plating” and “Pink Gold plating”

And if you realize that you want some unique Laser Cut resistant parts for outdoor activities, we offer you our waterproof Laser Cutting materials:

If you are ready to turn your idea into an actual product, do not hesitate to upload your 3D file on our platform, we will 3D print it and deliver it to you!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook