2 new CLIP resins available on Sculpteo!

Posted By Sculpteo on Jul 20, 2016 | 0 comments

We’re pleased to announce that two of our CLIP resins, Cyanate Ester, and Prototyping Acrylate, are exiting their beta phase and becoming available to the general public! We’re incredibly thankful for the feedback and data our testers have produced throughout the pilot program, and we hope that all testers will continue to enjoy the updates that we have implemented based on their feedback.

The Launch

March 1, 2016, you might remember the launch of our new Carbon 3D machine and with it the CLIP technology, that we offered in a Beta Pilot Program. We featured case studies from our happy customers and featured a few of them in previous blog posts, 3 months later in June we made the most popular of those materials available outside of the pilot program, that material is Rigid Polyurethane.

The time has come to take Cyanate Ester, and Prototyping Acrylate out of beta and offer those who did not participate in our pilot program the opportunity to create parts with these engineering and non-engineering resins. What does this mean for you? This is your opportunity to test out the materials for yourself and see what kind of finish and functionality these materials can provide.

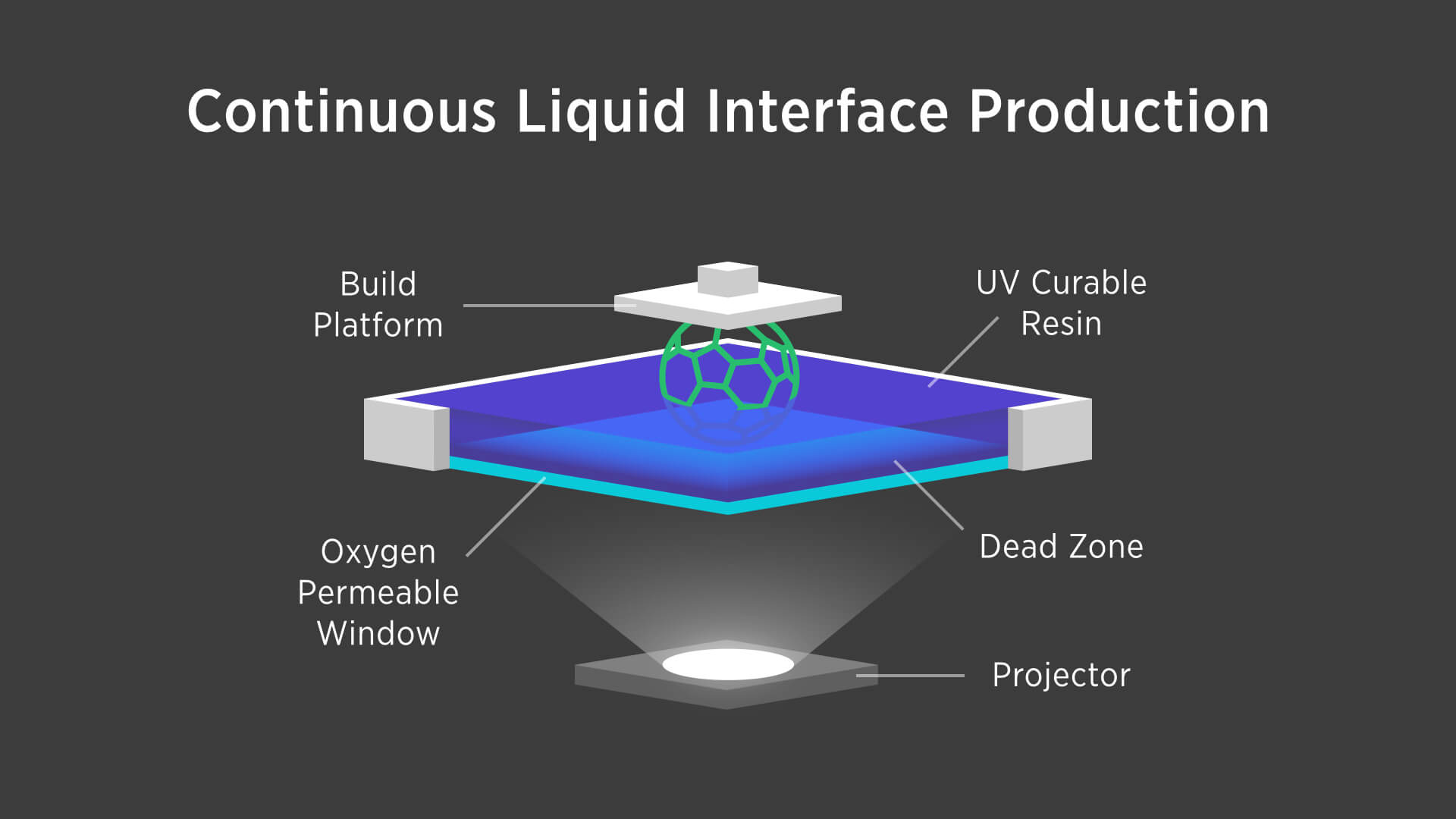

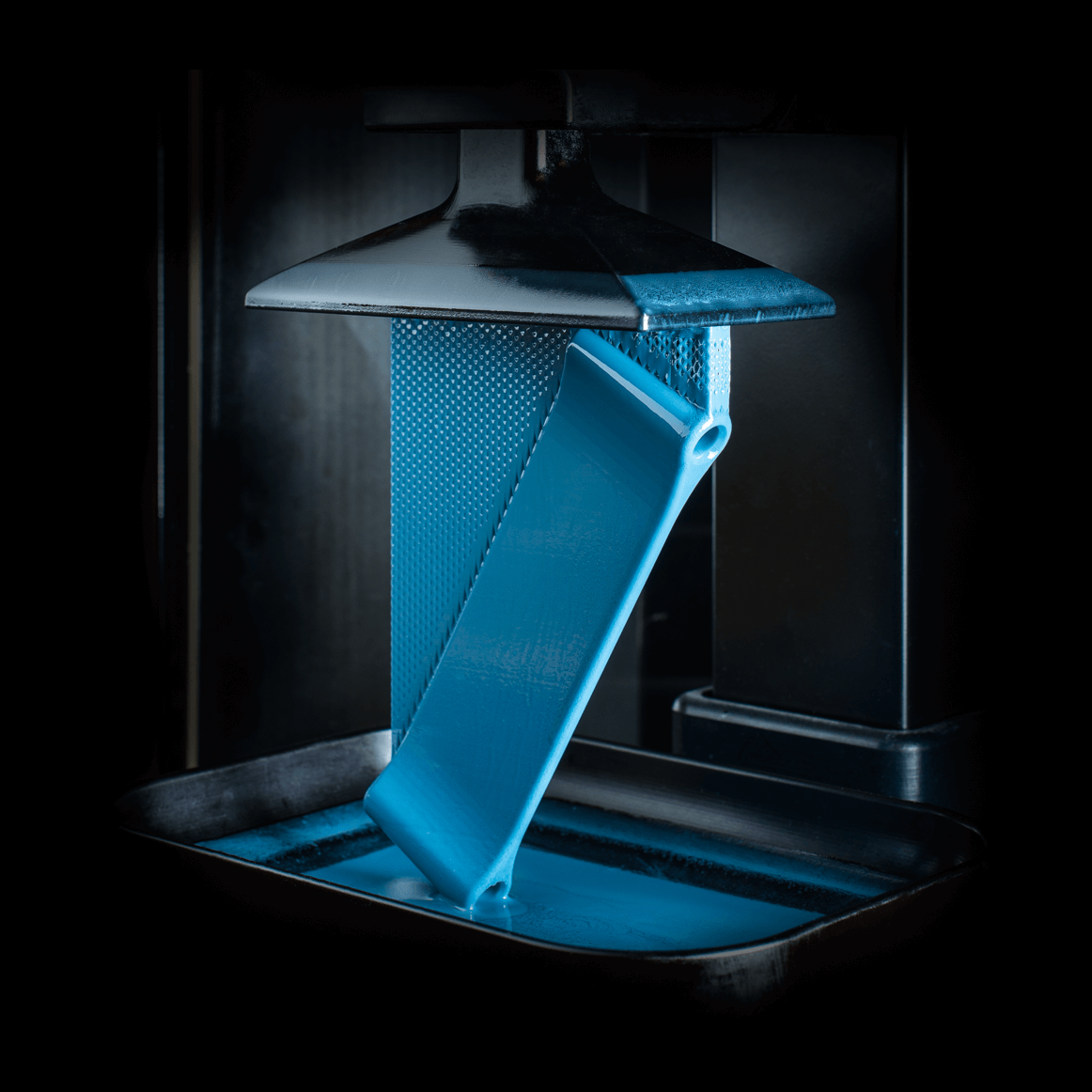

Just in case you need a refresher, CLIP, which stands for Continuous Liquid Interface Production, eliminates shortcomings of other 3D printing technology by emphasizing a tunable photochemical process over a traditional mechanical approach. CLIP works by projecting a continuous sequence of UV images, generated by a digital light projector, through an oxygen-permeable, UV-transparent window below a liquid resin bath. The dead zone created above the window maintains a liquid interface below the part. Above the dead zone, the curing part is drawn out of the resin bath. To learn more about the companies that have been a part of our pilot program, and to take a look behind the doors of our San Leandro, CA factory we created the video below:

Discoveries from our Pilot Program

Thanks to all the participants in the program we made several improvements to our CLIP 3D Printing service, and we could not have done it without the data that we received from our users. Below are a few bullets with information that we discovered from our pilot:

- Our Beta testers were very impressed with our RPU material, it is the most popular material for CLIP that we offer. Our Rigid Polyurethane resin material creates 3D printed objects from a base of photosensitive polymer liquid. That liquid is then solidified by UV light layer by layer to create rigid and highly detailed prints which are comparable to injection molded plastics. The final product has a naturally smooth and shiny surface.

- One of the biggest discoveries to come out of the pilot program is a list of the technical specifications for each available material. Before we began our CLIP Pilot Program we were not sure exactly what the design guidelines were for each material. However thanks to those who participated in the Beta, we were able to gather this data based on the orders we received. And we created the design guidelines for each material based on that data. For a list of the materials & their design guidelines please see them each listed below.

- Following your feedback, we also decided to add new colors for Prototyping Acrylate. You can now order directly in yellow, magenta, cyan, white, black and grey.

FAQ’s

Q: What materials are currently available for the CLIP program?

Currently, we have available: Rigid Polyurethane (RPU), Prototyping Acrylate, and Cyanate Ester. Elastomeric Polyurethane and Flexible Polyurethane are still in the Pilot program – which means when ordering a product in one of these materials, you’ll be asked to explain your project, and perhaps to redesign your file according to specific guidelines.

Q: How long does it take for my order to be shipped?

It can take anywhere from 1 to 9 days to ship your order, this depends on the finishes that you select and the general nature of your design.

Q: Are these materials waterproof?

Yes, they are all waterproof.

Q: What if my part cannot be printed with the selected material or CLIP technology?

If your part cannot be printed with a specific material or technology you will receive a message from us letting you know what these issues are, and recommending that you try a material/technology that might be better suited for your part.

Q: When will there be a flexible material available?

A flexible material, Flexible Polyurethane, is already available, but it’s still in the Pilot Program. As explained above, you will simply need to register when ordering in this material. Elastomeric Polyurethane is also very good material if you’re looking for flexibility.

We can’t wait to see what you will make with these two new resins.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook