SmithShaper: when 3D printing meets fitness

Posted By Allison Simonot on May 20, 2015 | 0 comments

3D printing is shaking up and innovating in all areas of business, like fitness, for example! See Marcus Smith’s story, an enthusiastic entrepreneur who is revolutionizing home fitness.

An ingenious idea is not enough to create an innovative product; you must still have the means to make your project come to life! This is a real challenge if you start from 0 and consider using traditional manufacturing methods: start up investment costs will be high and it is generally unsuitable for limited series production runs. Fortunately, 3D printing makes it much easier to transform an idea from concept to reality. It therefore opens the creative possibilities in all fields…including fitness, and more specifically, strength training for the back!

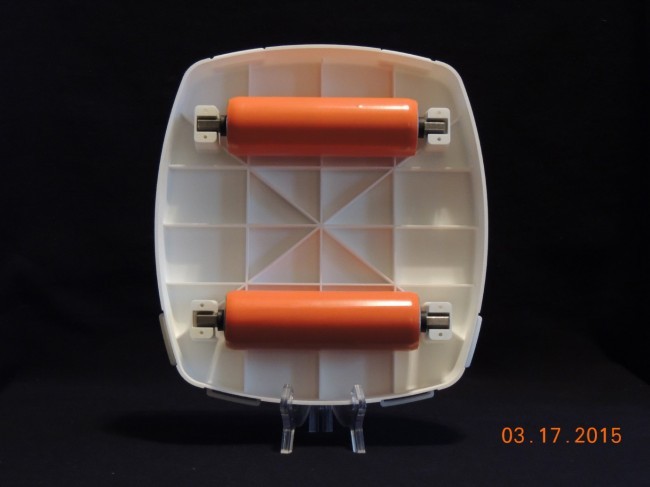

This is Marcus Smith’s story, a former bodybuilder and professional fitness and gym enthusiast, creator of the SmithShaper. His idea? To create a small, portable workout accessory, enabling everyone to do squats – a back strength training exercise. A squat is in fact a very common exercise in a gym, sometimes performed with the aid of a stability ball. But Marcus Smith’s experience made him want to create a specific piece of equipment, optimal and safe for the back.

If he began to create his prototype by himself, he needed to produce a more sleek-looking product to enter the market. Advised by a design engineer, this is when Sculpteo was brought into play:

“ I needed a working prototype but was not sure this was possible because using the SmithShaper requires users to wear the device like a backpack against a wall for squats. I was amazed that the model that Sculpteo produced was not only durable enough, but it can be used while holding 50 lb. dumbbells. I even still use it with no flaws.”

SmithShaper’s resistance is directly related to the quality of the material used: polyamide, an ideal material for mechanical objects. But beyond the satisfaction of having been able to produce an innovative object using 3D printing, Marcus Smith remembers the quality of Sculpteo’s online service, in particular. Unaccustomed to 3D printing, he especially appreciated how easy it was to use our 3D model uploading interface and its many optimisation tools to perfect his 3D model. This is what made the difference for him when starting up his entrepreneurial project.

The project is now launched on Kickstarter to distribute the SmithShaper! Also, you can get the latest news on its official website or its dedicated Facebook page.

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook