Meet Patrick Herbault, an inventor using 3D printing

Posted By Lucie Gaget on Oct 23, 2019 | 0 comments

We met Patrick Herbault, an inventor working with Sculpteo’s online 3D printing service to create his projects. How is 3D printing useful in his daily job and how is Sculpteo helping him to overcome the challenges of inventing? Let’s find out.

Can you present yourself?

After a career in the automotive industry, I now share my time between my own inventions and Applied Kinematics. In this company, I bring my R&D support to innovation, both for the development of new concepts, or to apply for patents.

What is your relationship with additive manufacturing?

In my job as an engineer, we have to be able to make some rapid prototyping, and there are a few solutions for that. One of them is to manufacture metal parts, mainly in aluminum or other types of materials such as plastic/nylon, able to represent an injection molded part in polypropylene. We have to make plans for the machining process anyway. But 3D printing is becoming a real alternative, even if this term is actually regrouping a lot of manufacturing techniques, sometimes quite old, such as Stereolithography. 3D printing technique has been quite democratized with filament 3D printers for individuals, but also with bigger solutions such as Sculpteo.

Since when do you use 3D printing, and why?

It’s been five years now since I use 3D printing (232 orders on Sculpteo since May 2014). I mainly use it for proof of concepts. For mass production, we use 3D printing to create parts identical in CAD to the injection molding mold in creation. This way we can start to make the mold and then start with the injection product.

Most of the time, this little development is made through several iterations on CAD, and then I need to validate it with a physical 3D printed representation, in order to start the whole tooling process and financial investments.

Can you tell us about your previous 3D printing experiments?

I now mostly use 3D printing for proof of concept, realistic parts made to get a confirmation of the technical and innovative proposition of the project. For example, it can be an innovative folding proposition we want to verify. More than just technically correct, the part has to be made in good quality, to convince anyone.

Indeed, if the product is not presentable, only technical interlocutors may understand the invention of your prototype. It is obviously better to create an object that everyone will understand and appreciate.

How do you create your 3D model and what 3D modeling software are you using?

As an inventor, I don’t have the professional skills of a designer when it comes to 3D modeling software, but I know how to create the parts I need. I use a free CAD tool, called FreeCAD, and I export my files in STEP format to 3D print them. In parallel, making CAD of these inventions allows creating figures if we want to apply for a patent.

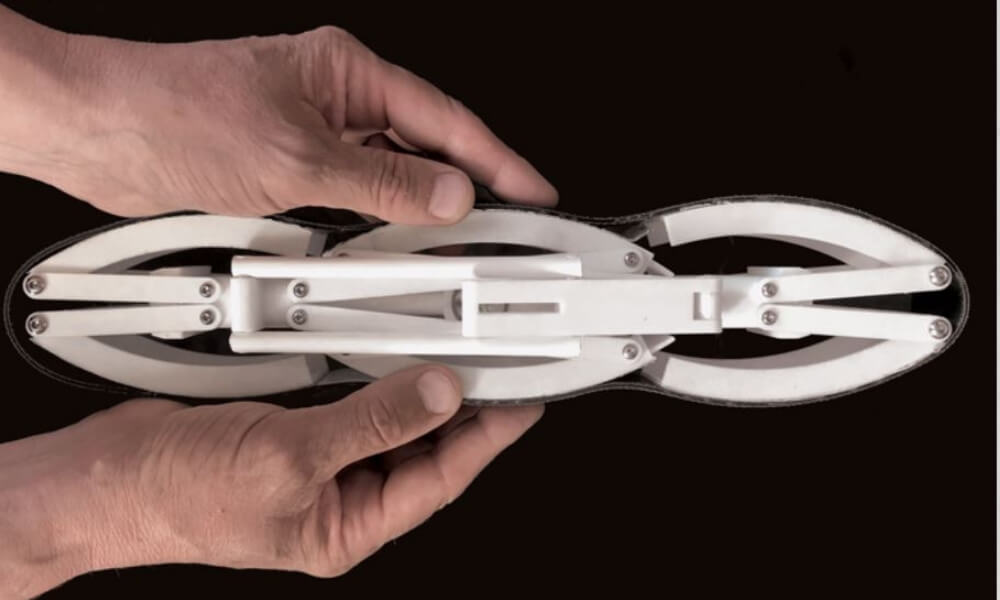

Can you tell us about your last invention, the foldable stroller wheels?

Some technical foldable wheel’s proposition already exists. In some cases, the wheel rim is cut in articulated sectors (6 to 8), allowing them to adopt a circle form when sectors are contiguous, and an elongated form when the wheel is bent.

If the tread, that is the part of the wheel in contact with the ground, is also cut, it will create a jerking movement when it will pass each sector. From my experience, I know it’s already unacceptable with handling trolley, or with any store trolley, so it is impossible to have this kind of dysfunction with a stroller. In this context, big wheels are often required, and foldable wheels fitting in the space of cabin baggage 25 x 35 x 55 cm. If the wheel has a 10” diameter (or 12.4 cm), it has to be removable, which is quite common now, or foldable wheels, a device that wasn’t existing yet.

For the childcare tradeshow of Kind + Jugend taking place in Cologne in September, I presented this new concept: a foldable stroller wheel. I applied for the patent in August. In this proposition the tire tread is continuous. In order to be as efficient as possible, I made the entire CAD file and 3D printed in most of the parts in plastic.

I built this prototype really quickly, with different CAD versions and different physical prototypes of the wheel to present it to the professional public of the tradeshow.

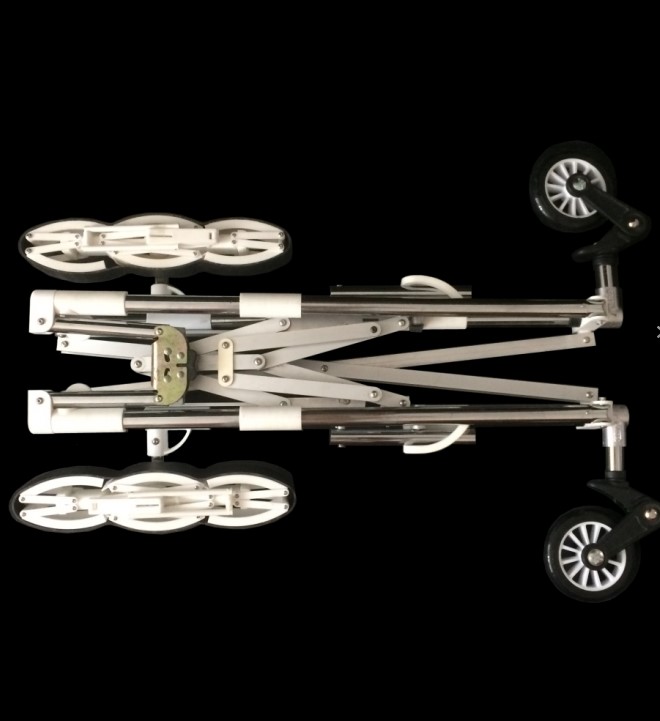

Moreover, for the tradeshow, I had two foldable stroller structures to go with these wheels. Thanks to Sculpteo I created six prototypes of foldable wheels (two for demonstrations, and two by stroller.) and two foldable stroller structures.

Why did you choose 3D printing to develop your prototypes and what are the advantages of this manufacturing technique for you?

3D printing is a proven rapid prototyping technique, it is immediate as you don’t need to have the material before, but also immediate in terms of orders, with an online quote and payment.

For my prototypes, I often start with a device already existing on the market, and I only modify a few parts: I use 3D printing to create these parts. Sometimes, it’s more about the combination of standard profiles in aluminum or plastic, round, square, oval or rectangular cut in the right dimensions, with 3D printed nozzles, connectors or hinges. That is what I did with my previous foldable strollers.

For the foldable wheel, all parts have been 3D printed except the tire tread in rubber, two ball bearings, and screws.

How is 3D printing bringing you more freedom?

3D printing is offering freedom while creating new innovations: the invented object can be built without having to worry about industrial possibilities. This manufacturing technique frees your mind of manufacturing constraints. Once it is invented and 3D printed as a prototype, it often appears that the object can be produced industrially. If not, the object invented will not have a great future, at least for mass production.

Why did you choose to develop your project using Selective Laser Sintering?

Selective Laser Sintering and Nylon PA12 are adapted to most of my projects:

- the result is robust enough to make the first try, and its aspect is realistic and close enough to an end product.

- the material is not easily breakable and can be modified

- Using Selective Laser Sintering is also offering the possibility to choose between 3 different prices regarding the delivery option you choose.

- Even if the SLS part doesn’t have the resistance of the metal material, it still allows to detect fragile area and modify the parts before starting to manufacture these parts in metal, which is way more expensive.

Did you try other 3D printing technologies?

Yes, I tried filament 3D printers but it doesn’t meet the professionalism I need for my parts. For flexible parts I mostly use rubber and other manufacturing solutions. And more rarely, I make some parts using metal 3D printing.

Why did you choose Sculpteo to manufacture your 3D printed parts?

First, the immediacy, as we can start the 3D printing process right away, with an instant quote (with other suppliers, we have to wait to get a quote, and it sometimes takes more time than the 3D printing process itself). Then, the possibility to adjust the price and delivery with some technologies such as SLS.

Sculpteo is also offering the possibility to upload a part and use some tools such as the hollowing tool. And, in some critical cases, we can also choose the orientation of the part.

Factory pick-up is also a good thing, as you can save a bit of time and get some technical advice directly on site. It is allowing me to work 7/7 days by picking my parts on Friday evening and working on it during the week-end!

Did this interview inspire you? Get ready to use our online 3D printing service.

Don’t hesitate to share your experience with us and subscribe to our newsletter to get all 3D printing news directly in your mailbox !

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook