Our 10 best tips to identify 3D printing opportunities for your business

Posted By Amandine Richardot on Jun 27, 2018 | 0 comments

Additive manufacturing can be a great asset for your business. It can truly help your company in becoming a true market leader. But, just like any great tool, it needs to be used in the right way. Indeed, using 3D printing is surely an asset, but not in all cases. Deploying a well-planned additive manufacturing strategy can help you reduce costs, build better products, and optimize your whole production process. You can use this technology for prototyping, of course, but also for production. But how can you know when it’s relevant or not to use 3D printing? Since Sculpteo was created, we got to observe numerous usages of additive manufacturing, and here are the best tips we can give you on how to identify 3D printing opportunities for your business.

In need of more guidance regarding the implementation of an additive manufacturing strategy? Our experts from Sculpteo Studio can give you a hand!

Analyze which parts of your manufacturing process take too much time

When you manufacture parts, time is precious: the faster you produce them, the bigger the amount of manufactured objects will be. 3D printing can speed up your manufacturing process on several aspects. For instance, if you waste too much time assembling parts after they’re produced, additive manufacturing can give you a hand, as we will see later on. If configuring your machines takes you too long, you can give a try to 3D printing, since it’s faster to start producing the part. Also, if creating molds for your objects makes your whole production process too slow, you should definitely take a look at the possibilities additive manufacturing offers. The only important thing here is to clearly evaluate your needs and the pain points you experience on a regular basis.

Configure your manufacturing line more efficiently

When you’re running a business, efficiency is key to achieve great results. Thus, you need to configure your production line in order to maximize its productivity. Unfortunately, such an optimization often requires multiple iterations, and they are costly both in time and money. Using 3D printing for these iterations could help you gain precious time. To know where you should start, just ask yourself what your least efficient processes are when it comes to the configuration of your line. Then, see which parts related to this precise operation could be modified, and 3D print them. That’s especially relevant when it comes to tooling.

Check which of your parts are not optimally designed due to manufacturing constraints

When using any manufacturing technique, you will meet some constraints related to the technology itself. They will impact your design for sure. Sometimes, that’s not really a big deal. But it can also be an issue and force you to have parts that are not at their best, just because you can’t achieve the desired result with such a technique. Indeed, subtractive manufacturing often implies some limits when designing your products. What if you started using 3D printing to push your objects one step further in terms of design, or at least free yourself from the constraints of other technologies? Indeed, additive manufacturing offers you more freedom on this aspect. As a result, evaluate which of your parts are in this situation, and check if 3D printing couldn’t give you the result you expect.

Evaluate which parts cost you too much money

Optimizing your costs is of course essential if you’re running a company. What if your parts could cost you less if you just changed the manufacturing technique you currently use? For many objects, 3D printing will be cheaper. It depends on the design, though: additive manufacturing is not always the cheapest option. But it’s important to evaluate that. For instance, if you need custom-made parts (such as tooling) or short series, this technology will be a key asset. Indeed, creating a mold or making the configurations on your complex CNC machines will be less cost-efficient. Moreover, some designs are hard to produce with traditional manufacturing techniques, but not with 3D printing. As a result, they could be cheaper if you use this technology.

Combine 3D printing and CNC to optimize your workflow

Here’s something important to mention: adopting 3D printing doesn’t require to stop using other manufacturing techniques such as CNC. Actually, combining several technologies is a great way to improve the efficiency of your whole manufacturing process. Indeed, they are not cost-efficient for the same things. For short-series and complex parts, 3D printing is perfectly suited. For a huge number of simple parts, CNC might be the best option. By combining both, you can get a more agile workflow, which can adapt easily to your evolving needs. If you want to learn more about this, you can read this blog post explaining how 3D printing can perfectly complement CNC.

Optimize your enclosures

If we dig a little bit deeper in terms of parts that are particularly relevant to manufacture with 3D printing, we obviously have to mention enclosures. Indeed, using additive manufacturing for these parts can truly help your business. First, 3D printing can help you create innovative shapes easily which can be a true asset for your product. Moreover, you will get your enclosures quickly. Also, it will be easy and not too costly to iterate multiple times. Finally, if you use parametric modeling, it will be very quick and simple to modify your enclosure afterwards: if some internal components change, if you need a smaller object, etc. Interested in this application of additive manufacturing? Discover our blog post on 3D printed enclosures.

Evaluate your needs in terms of part assembly

Another great design advantage of 3D printing is that you can integrate assembly features directly in your part. As a result, assembly time will be strongly reduced. Since additive manufacturing materials can be really robust, these parts of your objects will not break. Moreover, it will reduce costs since you won’t need to purchase other elements such as screws, and you will save precious time. There are multiple ways to connect two parts together using 3D printing. Joints and snap fits are a great option. Are you curious about this kind of connections that could be key for your products? You can read our tutorial on 3D printed joints and snap fits!

Improve your current fixtures in a cost-efficient way

Fixtures are also a very important kind of parts to produce with 3D printing. Indeed, several types of fixtures need to be custom-made, such as machining workholding, end-of-arm tooling, assembly and welding fixtures, and inspection fixtures. Redesigning them all the time and producing them with subtractive manufacturing doesn’t really make sense. As a result, many companies don’t customize their shape and just use one kind of fixtures to reduce their costs. Additive manufacturing clearly is a game-changer here: it makes them affordable.

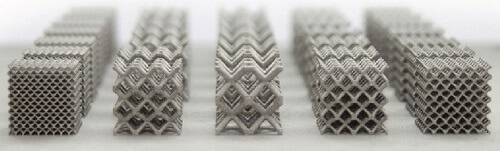

crédit: Altair Enlighten

Choose the parts you want to make lighter

Weight can often be a key feature of a product. How can you easily make your parts lighter? Using 3D printing! Indeed, you can easily make your objects weigh less thanks to several design tricks. For instance, you can hollow your objects to make them less dense in terms of materials. You can also insert lattices in your product, a specific design feature which creates some lightweight structures inside your part. Interested? Discover our blog post about lattice structures. If you want to generate some, read our post about the best lattice generation tools.

Use 3D printing to improve your whole maintenance process

When producing parts, things can go wrong with your machines. And replacing the broken parts can be complicated, and waste precious time. With additive manufacturing, you can create replacement parts for your machines quickly. It’s faster than creating a mold and then manufacturing your part. Thus, using 3D printing, broken machines will have less impact on your workflow thanks to an optimized maintenance process.

Do you need a hand to identify the best 3D printing opportunities?

These tips might not be sufficient to guide you completely in your implementation of additive manufacturing in your business. No problem, our experts are here to guide you! Sculpteo Studio is our 3D printing consulting service. Discover their design, consulting and training services now!

Connect with Google

Connect with Google Connect with Facebook

Connect with Facebook